- ALFRAN - OUR HOUSE BRAND

- Pipes

- Fittings

- Valves

- SOLAR PV SYSTEM

- Accessories

- Building Materials

- KITCHEN SERIES

- BATHROOM SERIES

- OTHERS - NON BUILDING MATERIALS

Galvanised Iron (GI) Pipe Fittings, Joints & Connectors

May, 09 2024

Author: Unitrade

Share This With

GI pipe fittings, or galvanized steel pipe fittings, play a vital role in modern plumbing systems. Made of galvanized iron, these fittings are unique in their ability to resist corrosion, making them perfect for use in irrigation, water and gas distribution, sewer, and HVAC systems. Their versatility is also crucial in industrial projects.

Affordable and accessible, this guide delves deeper into the up-and-coming material in the market: GI pipe fittings.

What Are Galvanised Iron (GI) Pipe Fittings?

GI pipe fittings, also known as galvanized pipe connectors, are essential components of plumbing systems made from galvanized iron pipes. These steel pipes are coated with zinc to prevent rust and corrosion, enhancing their durability. Typically threaded, these connectors are used to control flow, change the direction of fluids and gases, and ensure secure pipe installations in both residential and commercial settings.

Types of GI Pipe Fittings

The array of GI pipe fittings includes various types such as elbows, tees, reducers, couplings/unions, caps, plugs, flanges, and nipples. Each type serves a specific purpose within plumbing systems, ensuring efficient fluid and gas transportation in diverse environments, from residential complexes to industrial facilities.

Elbows

Elbows are used to change the direction of the pipe run. They come in different angles such as 45 degrees and 90 degrees.

Tees

Tees create a branch in a pipeline, allowing flow in two directions perpendicular to the main flow direction.

Reducers

Reducers connect pipes of different diameters, allowing for a change in pipe size within the plumbing system.

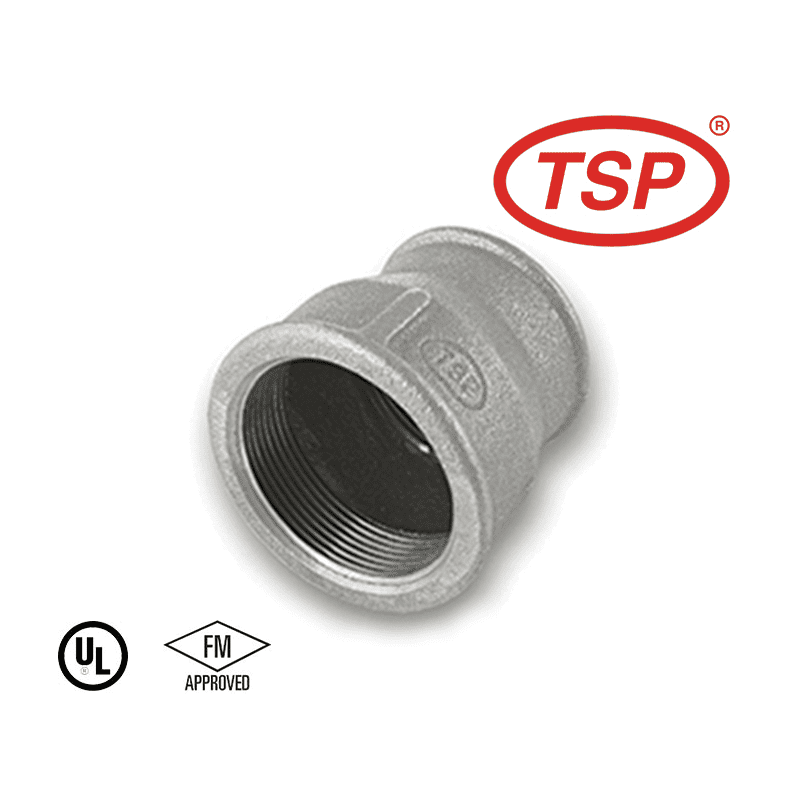

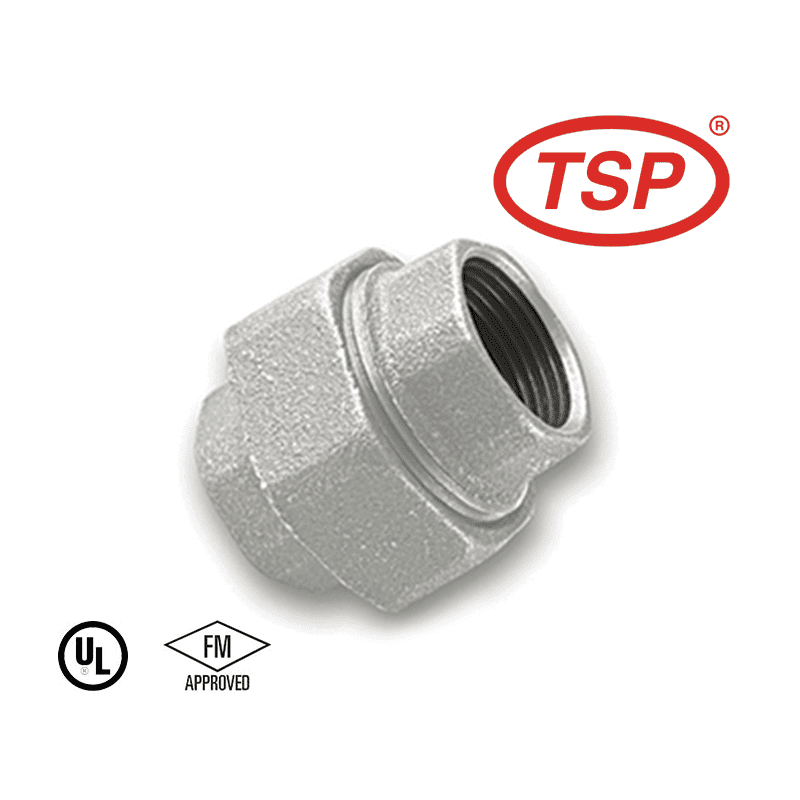

Couplings/Unions

Couplings connect two pipes of the same diameter in a straight line. Unions are similar to couplings but allow for easy disassembly of pipes for maintenance or repairs.

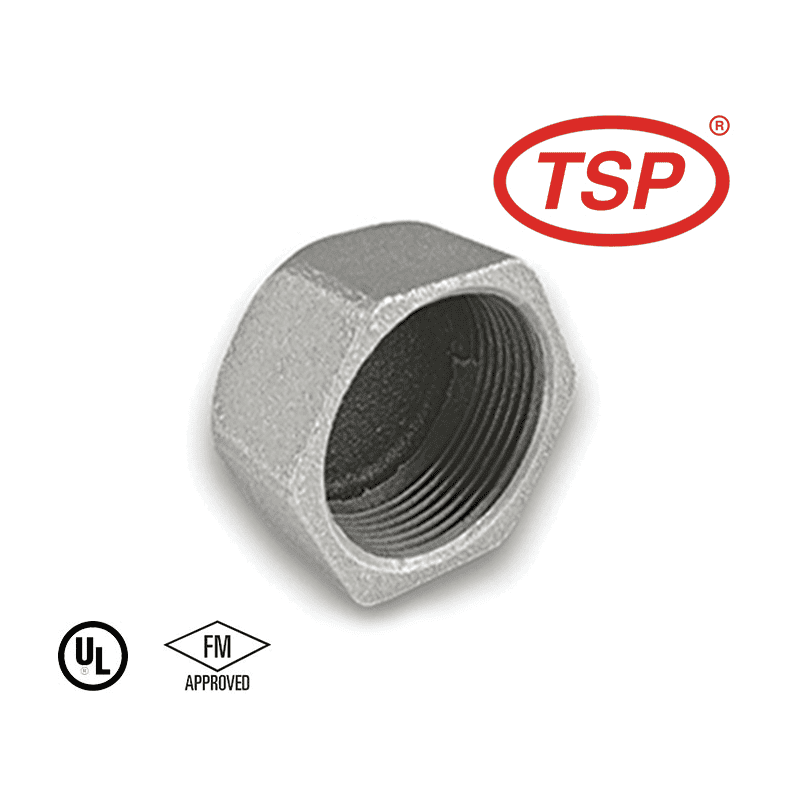

Caps

Caps are used to seal the end of a pipe. They are commonly used when a pipe end needs to be closed permanently.

Plugs

Plugs are similar to caps but are designed to be inserted into the end of a pipe to block the flow temporarily.

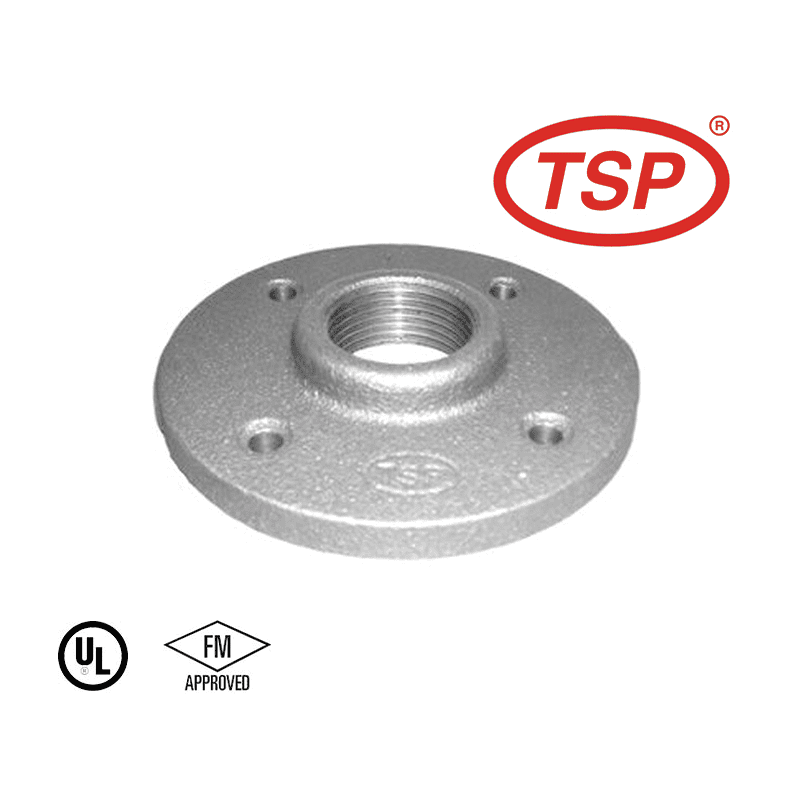

Flanges

Flanges connect pipes, valves, and other equipment to form a piping system. They allow for easy assembly and disassembly of components.

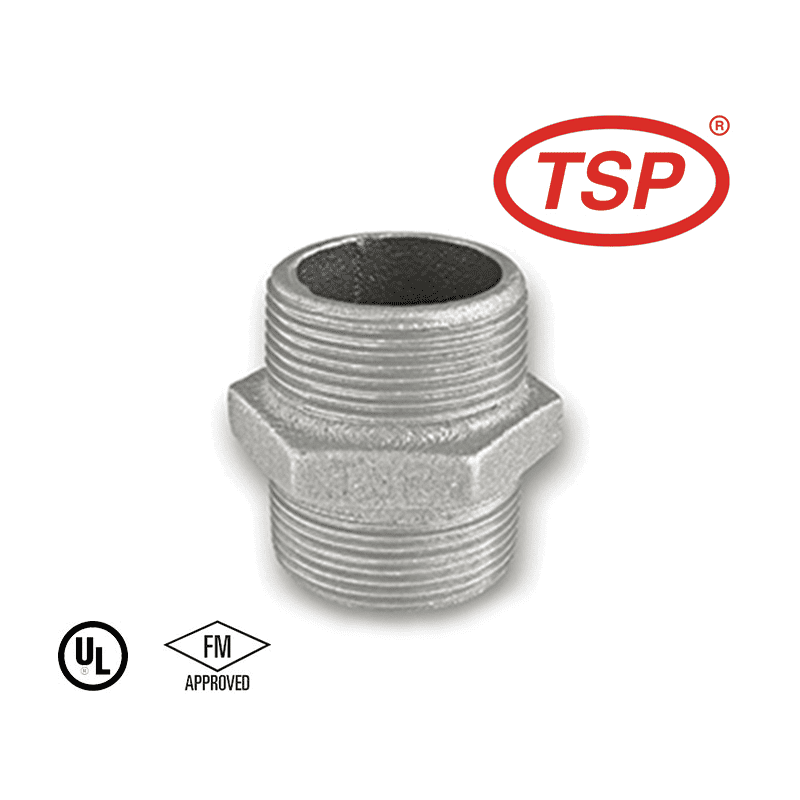

Nipples

Nipples are short sections of pipes with male threads on both ends. They are used to extend a pipe length or to connect two fittings.

GI Pipe Sizing

GI pipes are available in various sizes and schedules, which determine their pressure ratings and applications. Small diameter GI pipes are commonly used in residential plumbing, while medium and large diameter pipes are ideal for commercial and industrial uses. The wall thickness of these pipes, denoted by their schedule, affects their structural integrity and suitability for different pressures and loads.

Small Diameter GI Pipes (1/8″ to 2″)

Small diameter GI pipes, ranging from 1/8 inch to 2 inches in diameter, are commonly used for residential plumbing applications and aid with water distribution, drainage and plumbing ventilation for buildings.

Medium Diameter GI Pipes (2″ to 6″)

Medium diameter GI pipes, ranging from 2 inches to 6 inches in diameter. These are often used in residential, commercial, and industrial applications for distributing water from main water supply lines, water irrigation systems, industrial process piping, and easier plumbing installation in smaller commercial buildings.

Large Diameter GI Pipes (6″ and above)

Large diameter GI pipes, with a diameter of 6 inches and above, are primarily used in industrial and infrastructure projects for You can municipal water supply and distribution systems, sewer and drainage systems, oil and gas pipelines, power plants, and chemical processing facilities.

GI Pipe Fitting Widths

GI pipes are available in different thicknesses, referred to as schedules. The thickness of GI pipes is important as it affects the pressure rating, structural integrity, and suitability for various applications. The most common thicknesses of GI pipes include:

Schedule 40

Schedule 40 GI pipes have a medium wall thickness and are commonly used in residential and commercial plumbing applications. They are suitable for low to medium-pressure applications and are widely used for water supply lines, drainage systems, and general plumbing installations.

Schedule 80

Schedule 80 GI pipes have a thicker wall when compared to Schedule 40 pipes, providing a higher pressure rating and increased structural strength. They are commonly used in industrial applications and heavy-duty plumbing installations, as higher pressure or load-bearing capacity is required. Examples include industrial process piping, high-pressure water lines, and underground utility installations.

Schedule 160

Schedule 160 GI pipes have an even thicker wall when compared to Schedule 80 pipes, offering higher pressure ratings and greater durability. They are used in specialised applications where extreme pressure or harsh operating conditions are encountered, such as in chemical processing plants, refineries, and high-pressure steam systems.

Extra Heavy (XS) and Double Extra Heavy (XXS)

Extra Heavy (XS) and Double Extra Heavy (XXS) GI pipes have walls thicker than Schedule 80, providing exceptionally high-pressure ratings and structural integrity. They are typically used in specialised industrial applications, including oil and gas pipelines, power generation facilities, and offshore platforms with extreme pressures and corrosive environments.

Uses for GI Pipe Fittings

From water supply systems and gas distribution networks to sanitary and drainage systems, GI pipe fittings are indispensable. They are also crucial in fire protection systems, HVAC setups, and irrigation infrastructures. The robustness of galvanized iron makes these fittings suitable for harsh outdoor environments and demanding industrial applications.

- Water Supply Systems: GI pipe fittings are extensively used in residential and commercial buildings for distributing potable water. Their corrosion-resistant properties ensure long-lasting, reliable delivery of clean water.

- Gas Distribution Systems: These fittings are crucial in safely transporting natural gas or propane in both residential and industrial settings, thanks to their durability and leak-proof nature.

- HVAC Systems: GI fittings play a key role in HVAC systems, facilitating the efficient movement of hot or cold air through ducts, contributing to optimal indoor temperature control.

- Plumbing and Sanitation: GI pipe fittings are employed to construct robust drainage and sewage systems, effectively managing wastewater disposal and stormwater drainage in urban infrastructure.

- Irrigation Systems: Used in agriculture, GI pipe fittings help in constructing irrigation systems that distribute water evenly across large fields, ensuring adequate water supply for crop cultivation.

Advantages of Using GI Pipes

Galvanized iron pipe fittings offer several benefits, including corrosion resistance, durability, strength, and ease of installation. Their versatility allows them to meet the diverse needs of various applications, such as water supply, drainage, gas distribution, and even structural support and frameworks in construction projects.

- Corrosion Resistance: Galvanization coats iron or steel pipes with zinc, guarding against corrosion and rust from water, soil, and other elements, ensuring extended piping system lifespan.

- Durability: GI pipe fittings endure mechanical stress, pressure, and temperature changes common in plumbing systems, offering longevity and reducing maintenance needs.

- Strength: Galvanised iron pipes and fittings boast high tensile strength, ideal for high-pressure systems and rugged industrial environments.

- Fire Resistance: Galvanised iron inherently resists fire, making GI pipe fittings suitable for fire protection systems and areas prioritising fire safety.

- Environmental Friendliness: Zinc used in galvanisation is recyclable, promoting sustainability. Extended service life reduces replacements, contributing to resource conservation.

GI Pipe Fittings Pricing

The cost of GI pipe fittings can vary based on size, type, and brand. However, they are generally considered cost-effective solutions for both small-scale residential projects and large-scale industrial applications. At Unitrade, Malaysia’s leading GI pipe fittings supplier, they can go from RM 2-RM 265 per piece.

GI Pipe Fittings Supplier Malaysia

GI pipe fittings are a reliable and accessible component of plumbing systems everywhere. With their zinc coat for extra resistance and compatibility with many materials, they are a sought-after material in the industry.

With any construction project, the correct materials are a necessity to achieve the best results and ensure future damage and destruction can be mitigated. As such, consultation with the right contractors and company is a sure-fire way to set yourself up for success. Contact Unitrade today for top-tier GI pipe fittings at your disposal.

FAQ

What types of GI pipe fittings are available?

We offer a wide range of GI pipe fittings suitable for various applications, including Pipe Elbows, Pipe Caps, Pipe Plugs, Pipe Unions, Pipe Crosses, and different types of Pipe Reducers such as Pipe Reducer Nipples and Pipe Reducer Sockets. Our extensive pipe fittings sales catalog provides details on each type, including galvanized pipe sizes and specifications to help you choose the right fitting for your needs.

Are GI pipe fittings suitable for outdoor applications?

Yes, GI pipe fittings are highly suitable for outdoor applications due to their exceptional corrosion resistance, primarily attributed to the protective zinc coating applied during galvanisation. As a result, GI fittings maintain their structural integrity and durability even when exposed to harsh weather conditions and temperature variations, making them a reliable choice for outdoor installations requiring long-term performance and reliability.

How long do GI pipe fittings last?

The lifespan of GI pipe fittings depends on various factors such as environmental conditions, fluid properties, and maintenance practices. With proper installation and maintenance, GI pipe fittings can last for decades. However, environmental factors and weather conditions can reduce the lifespan of GI fittings if excessive.

Are GI pipe fittings suitable for drinking water applications?

Yes, GI pipe fittings are commonly used for drinking water applications in residential, commercial, and industrial settings. The zinc coating provides a protective barrier, ensuring the safety and quality of the drinking water.

How do you maintain GI pipe fittings?

Regular maintenance of GI pipe fittings involves inspecting for signs of corrosion, leaks, or damage, and addressing any issues promptly. Cleaning, lubricating, and replacing fittings as needed can help extend their lifespan and performance.

-

Category

Construction & Buildings -

Tags

Everything You Need to Know About Poly Pipe: A 2024 Guide

Read moreForging the Future: A Comprehensive Guide to The Enduring Legacy of Structural Steels in Construction (2024)

Read moreA Guide to Mastering Pressure Switches: Functionality, Applications, and Maintenance (2024)

Read moreMastering Pipe Fittings: A Comprehensive Guide to Selection, Prevention, Reuse, and Measurement (2024)

Read moreChoosing Between PVC and Poly Pipes: A Comprehensive Comparison (2024)

Read moreGalvanised Iron (GI) Pipe Fittings, Joints & Connectors

Read moreWhat is Fibreglass Insulation (Pros and Cons, Alternatives)

Read moreStainless Steel Flexible Hose Guide & Supplier Malaysia (2024)

Read moreWhat are uPVC Fittings? (Types, Advantages, Applications)

Read morenewsletter Subscription

Sign Up Now & Stay Tune With Our Latest News & Product Updates!