- ALFRAN - OUR HOUSE BRAND

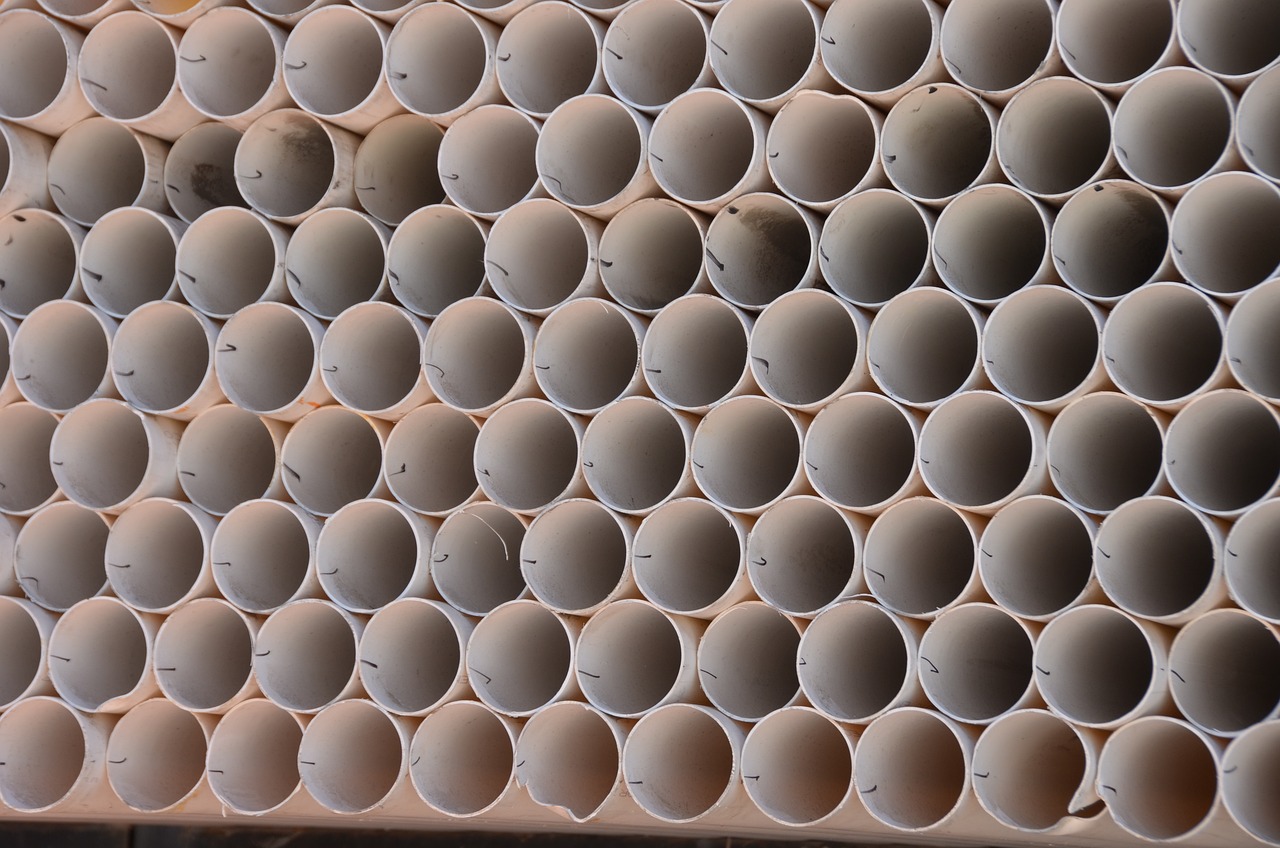

- Pipes

- Fittings

- Valves

- SOLAR PV SYSTEM

- Accessories

- Building Materials

- KITCHEN SERIES

- BATHROOM SERIES

- OTHERS - NON BUILDING MATERIALS

Everything You Need to Know About Poly Pipe: A 2024 Guide

June, 03 2024

Author: Unitrade

Share This With

Polyethylene pipes, or poly pipe for short, have steadily become a staple for plumbing and industrial projects. From the 1930s till now, they have served as a more flexible and accessible resource for contractors worldwide.

Made from a thermoplastic material, poly pipes are well known for their uses in the industrial, commercial, and agricultural markets.

What are Poly Pipes?

Poly pipes are plastic piping commonly used in plumbing, irrigation, and other fluid transfer applications. They are made from polyethylene, a durable and flexible thermoplastic material.

Poly pipes come in various diameters and are available in different types, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE), each with specific applications and characteristics. They are commonly used in residential plumbing for water supply lines, agricultural irrigation systems, and industrial applications for transporting chemicals and other fluids.

Types of Poly Pipes

Poly pipes come in various types, each designed for specific applications and performance requirements. The main types of poly pipes include:

- High-Density Polyethylene (HDPE): HDPE pipes have high density and stiffness, which offer excellent strength and durability and make them most suitable for high-pressure applications like water supply, irrigation, gas distribution, industrial fluid transport, and mining.

- Medium-Density Polyethylene (MDPE): MDPE pipes, with lower density and stiffness than HDPE, suit lower-pressure uses like gas distribution, water supply, and irrigation. They provide good flexibility which helps them resist cracking, and are ideal for underground installations.

- Low-Density Polyethylene (LDPE): LDPE pipes, with the lowest density and stiffness, are flexible and easy to handle. They are used for drip irrigation, landscaping, and low-pressure water distribution.

- Cross-linked Polyethylene (PEX): PEX pipes undergo cross-linking for improved thermal and mechanical properties, and are common in plumbing for hot and cold water distribution, and radiant floor heating. Overall, they offer flexibility, corrosion resistance, and durability.

- Polybutylene (PB): Poly-B pipes, akin to polyethylene but from polybutylene resin, were once common in residential plumbing. These types of pipes, however, fell out of favour due to concerns about long-term reliability and degradation susceptibility.

The choice of poly pipe type depends on factors such as pressure requirements, temperature limitations, flexibility, and compatibility with the specific application and environment.

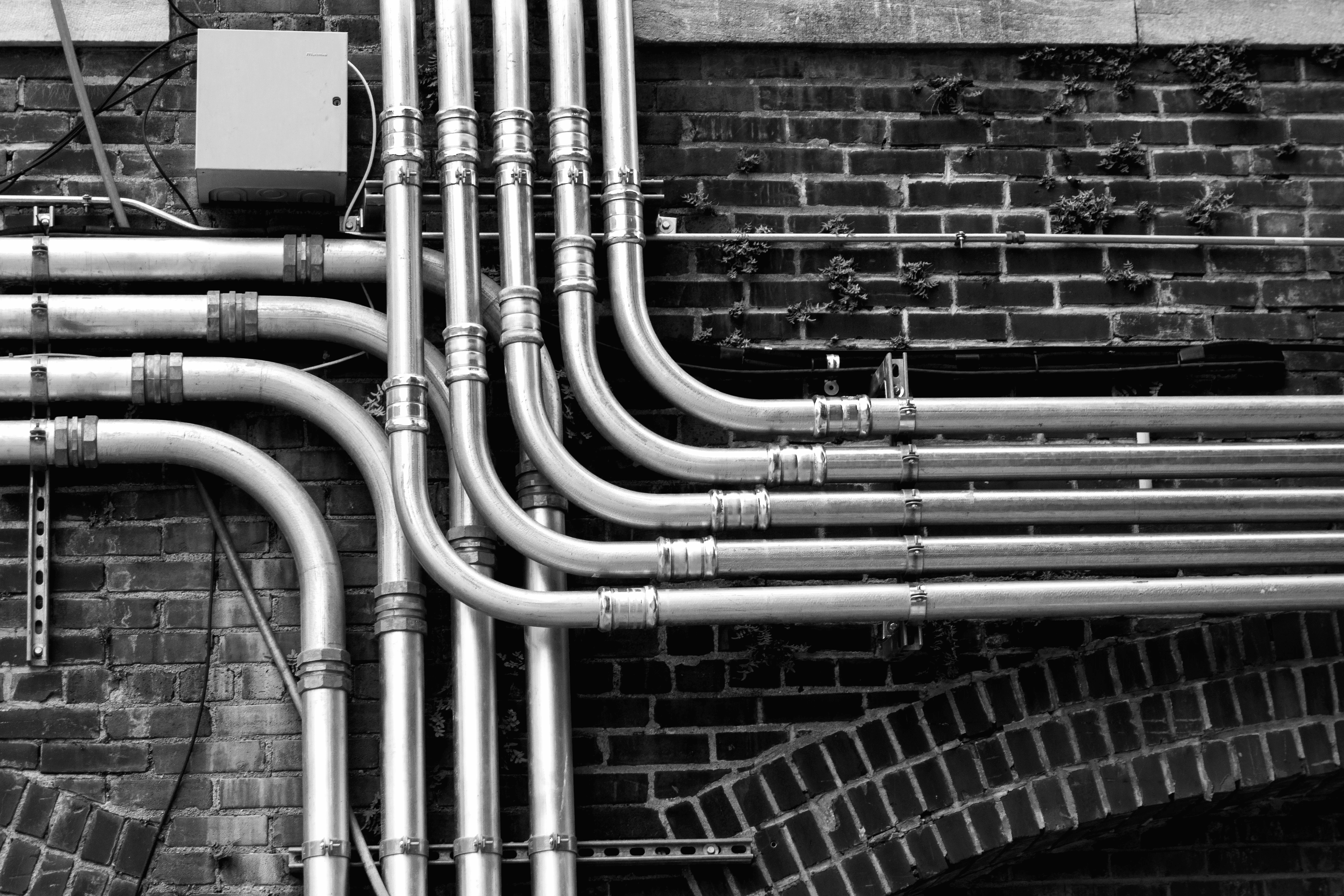

Uses of Poly Pipes

Poly pipes are used for various applications due to their versatility, durability, and cost-effectiveness. Some common uses include:

Water Supply

Poly pipes are frequently used in water supply systems, both for municipal water distribution and private well systems. They can handle cold and hot water and are suitable for above-ground and underground installations.

Irrigation

In agricultural settings, poly pipes are extensively used for irrigation systems to transport water to crops. Their flexibility allows for easy installation around fields, and they are resistant to damage from exposure to sunlight and soil chemicals.

Drainage and Sewer Systems

Polyethylene pipes are also utilised in drainage and sewer systems, especially in areas where corrosion is a concern due to soil conditions or chemicals.

Natural Gas and Propane Distribution

Poly pipes are suitable for transporting natural gas and propane in residential and commercial settings. They offer a safer and more cost-effective alternative to traditional metal pipes for gas distribution.

Geothermal Systems

Poly pipes are used in geothermal heating and cooling systems. They circulate water or heat-transfer fluids underground to harness the earth’s natural temperature for heating and cooling buildings.

Industrial Applications

Poly pipes are used in various industrial settings to transport chemicals, acids, and other fluids. Their resistance to corrosion and chemical degradation makes them suitable for handling a variety of substances.

Telecommunications

Some poly pipes are specifically designed to protect underground telecommunication cables and conduits. These pipes provide a protective casing that helps prevent damage from external factors such as moisture and soil conditions.

Poly Pipes vs Poly B Pipes

Poly pipes (polyethylene pipes) and Poly-B pipes (polybutylene pipes) are two types of plastic piping commonly used in plumbing and fluid transport. Poly pipes are made from polyethylene, known for flexibility, durability, and corrosion resistance. Poly-B pipes are made from polybutylene, used in plumbing from the 1970s to 1990s. Poly pipes are generally better than Poly-B pipes due to:

- Durability and Resistance to Degradation: Polyethylene pipes resist degradation from chemicals and UV radiation, maintaining integrity. Poly-B pipes are prone to premature deterioration and failure, especially from chlorine.

- Flexibility and Stress Resistance: Polyethylene pipes withstand ground movement and temperature fluctuations without leaks. Poly-B pipes are less flexible and prone to stress-related failures.

- Water Quality Compatibility: Polyethylene pipes are compatible with various water qualities, and are resistant to corrosion. Poly-B pipes deteriorate faster in environments with high chlorine levels.

- Usage History and Confidence: Polyethylene pipes have a proven track record of reliability. Poly-B pipes have a troubled history with widespread failures, leading to decreased use.

- Regulatory and Insurance Considerations: Poly-B pipes may not meet current building codes, and insurance coverage might be limited due to reliability concerns. Polyethylene pipes typically meet industry standards and codes.

Overall, polyethylene pipes offer superior durability, flexibility, and resistance to degradation, making them a more reliable option for plumbing and fluid transport than polybutylene pipes.

Poly Pipes vs PVC Pipes

Poly pipes and PVC pipes share similarities and differences in their composition, applications, and characteristics. Both types of pipes are made from thermoplastic materials, providing flexibility and resistance to corrosion. They are commonly used in plumbing, irrigation, and fluid transport applications. However, there are some key differences between the two:

- Flexibility: Poly pipes are highly flexible, allowing for easier installation without additional fittings, while PVC pipes are rigid and require fittings for directional changes.

- Temperature Resistance: Poly pipes may have lower temperature resistance than PVC pipes.

- Cost: Poly pipes are often more cost-effective than PVC pipes, in terms of material cost and installation expenses.

- Chemical Resistance: PVC pipes exhibit better resistance to certain chemicals and corrosion than poly pipes.

Ultimately, the choice between poly and PVC pipes depends on specific project requirements and preferences for flexibility, installation ease, and temperature resistance.

Advantages of Poly Pipes

Using poly pipes (polyethylene pipes) offers several advantages for various applications. Some of the key pros of using poly pipes include:

- Corrosion Resistance: Poly pipe resist corrosion from chemicals, soil, and electrolysis, ideal for underground installations.

- Flexibility: Poly pipe bend easily without extra fittings, simplifying installation and reducing leaks

- Durability: Polyethylene pipes last long, resisting UV rays, chemicals, and extreme temperatures for above and below-ground use.

- Chemical Resistance: Poly pipes don’t react with substances, suitable for transporting various fluids without contamination.

- Low Friction Loss: Smooth inner walls reduce friction, enhancing flow rates and system performance.

- Cost-Effectiveness: Poly pipes are cheaper than metal pipes, saving on materials and installation.

- Versatility: Polyethylene pipe suits diverse applications like water supply, irrigation, drainage, and industrial use.

- Longevity: Properly maintained poly pipes last decades, reducing replacement needs.

- Safety: Polyethylene doesn’t leach toxins, ensuring safe transport of potable water and other liquids.

The pros of using poly pipes make them a popular choice for a wide range of applications in plumbing, agriculture, construction, and industrial sectors.

Safety Of Poly Pipes

Poly pipe, particularly polyethylene pipes, are considered safe for various applications, including plumbing, irrigation, and fluid transport when manufactured, installed, and maintained correctly.

Safety in Installation and Use

There are a variety of factors that lend to why poly pipes are safe to use in fluid transport systems, such as:

- Material Safety: Polyethylene, used for poly pipes, is non-toxic and chemically inert, ensuring it doesn’t leach harmful substances into water or fluids.

- Corrosion Resistance: Poly pipes resist corrosion from chemicals, soil conditions, and electrolysis, suitable for underground installations.

- Durability: Polyethylene pipes have a long service life, resisting UV degradation and withstanding various temperatures and conditions.

- Flexibility: Due to their flexibility, poly pipes can handle ground movement and seismic activity without rupturing or leaking.

- Standards Compliance: Poly pipes meet industry standards and regulations, ensuring safety and performance.

Safety From Heat Exposure

Polyethylene (PE) pipes, including variants like high-density polyethylene (HDPE) and low-density polyethylene (LDPE), have limited heat resistance compared to metallic or CPVC piping materials. HDPE pipes typically withstand continuous service temperatures ranging from 140°F to 180°F (60°C to 82°C), whereas LDPE pipes soften or deform at temperatures surpassing 120°F (49°C). Before attempting to install anything with poly pipe, specifications should be gathered from manufacturer consultation to ascertain the maximum temperature tolerance of the polyethylene pipe in use, particularly in applications requiring elevated temperatures like hot water distribution or industrial processes. In such cases, alternative piping materials with superior temperature resistance may be more suitable.

Safety For Water Consumption

Despite possible public fears, Poly pipe, specifically those made from polyethylene (PE), are safe for transporting drinking water. There are a variety of reasons why this is the case:

- Non-Toxic Material: Polyethylene doesn’t leach harmful substances into water.

- Chemical Inertness: Polyethylene doesn’t react with water, ensuring minimal interaction and maintaining water quality.

- Corrosion Resistance: Poly pipes resist corrosion, ensuring water quality by eliminating the risk of contamination.

- Standards Compliance: Polyethylene pipes for drinking water meet strict industry standards, ensuring safe conveyance.

- Longevity and Durability: Polyethylene pipes have a long service life, resisting degradation and providing reliable water transport.

It’s crucial to install and maintain polyethylene pipes correctly, following manufacturer recommendations and industry practices, to ensure safe and reliable water transport. Regular inspection and adherence to local regulations are essential to maintain safety and compliance.

Poly Pipes Supplier Malaysia

Poly pipes are one of the most popular types of pipes in the market today. From their ease of installation to their assured quality, they are a prime component to use in your projects today.

It is imperative to ensure that you select the right manufacturer, as it can impact the quality of your products and your construction project. That is where Unitrade comes in, offering high-quality industrial products. To see what Unitrade has to offer for poly pipes and get a consultation from their specialists, visit their website today.

FAQ

What are poly pipes made of?

Poly pipes are primarily composed of thermoplastic materials, commonly polyethylene (PE) or polybutylene (PB). These materials offer flexibility, durability, and resistance to corrosion, making them suitable for various plumbing and fluid transport applications.

How do poly pipes compare to other types of pipes?

Poly pipes offer distinct advantages over alternative piping materials. They are more flexible and are less likely to corrode over time, making them suitable for a wider range of applications. However, they have lower temperature resistance when compared to certain materials like CPVC, making them less universally usable.

Are poly pipes suitable for underground installation?

Yes, poly pipes are commonly used for underground applications due to their flexibility and resistance to corrosion. Proper installation techniques, such as burying them at the appropriate depth and using adequate support, can help ensure their longevity and performance underground.

How long do poly pipes last?

Poly pipes are known for their durability and can last for several decades when properly installed and maintained. However, external factors such as environmental conditions and water quality can affect their lifespan.

What precautions should I take when installing poly pipes?

When installing poly pipes, it is essential to follow manufacturer recommendations and industry best practices. This includes using proper jointing techniques, providing adequate support to prevent sagging or stress on the pipes, and considering thermal expansion and contraction.

-

Category

Construction & Buildings -

Tags

Everything You Need to Know About Poly Pipe: A 2024 Guide

Read moreForging the Future: A Comprehensive Guide to The Enduring Legacy of Structural Steels in Construction (2024)

Read moreA Guide to Mastering Pressure Switches: Functionality, Applications, and Maintenance (2024)

Read moreMastering Pipe Fittings: A Comprehensive Guide to Selection, Prevention, Reuse, and Measurement (2024)

Read moreChoosing Between PVC and Poly Pipes: A Comprehensive Comparison (2024)

Read moreGalvanised Iron (GI) Pipe Fittings, Joints & Connectors

Read moreWhat is Fibreglass Insulation (Pros and Cons, Alternatives)

Read moreStainless Steel Flexible Hose Guide & Supplier Malaysia (2024)

Read moreWhat are uPVC Fittings? (Types, Advantages, Applications)

Read morenewsletter Subscription

Sign Up Now & Stay Tune With Our Latest News & Product Updates!