- ALFRAN - OUR HOUSE BRAND

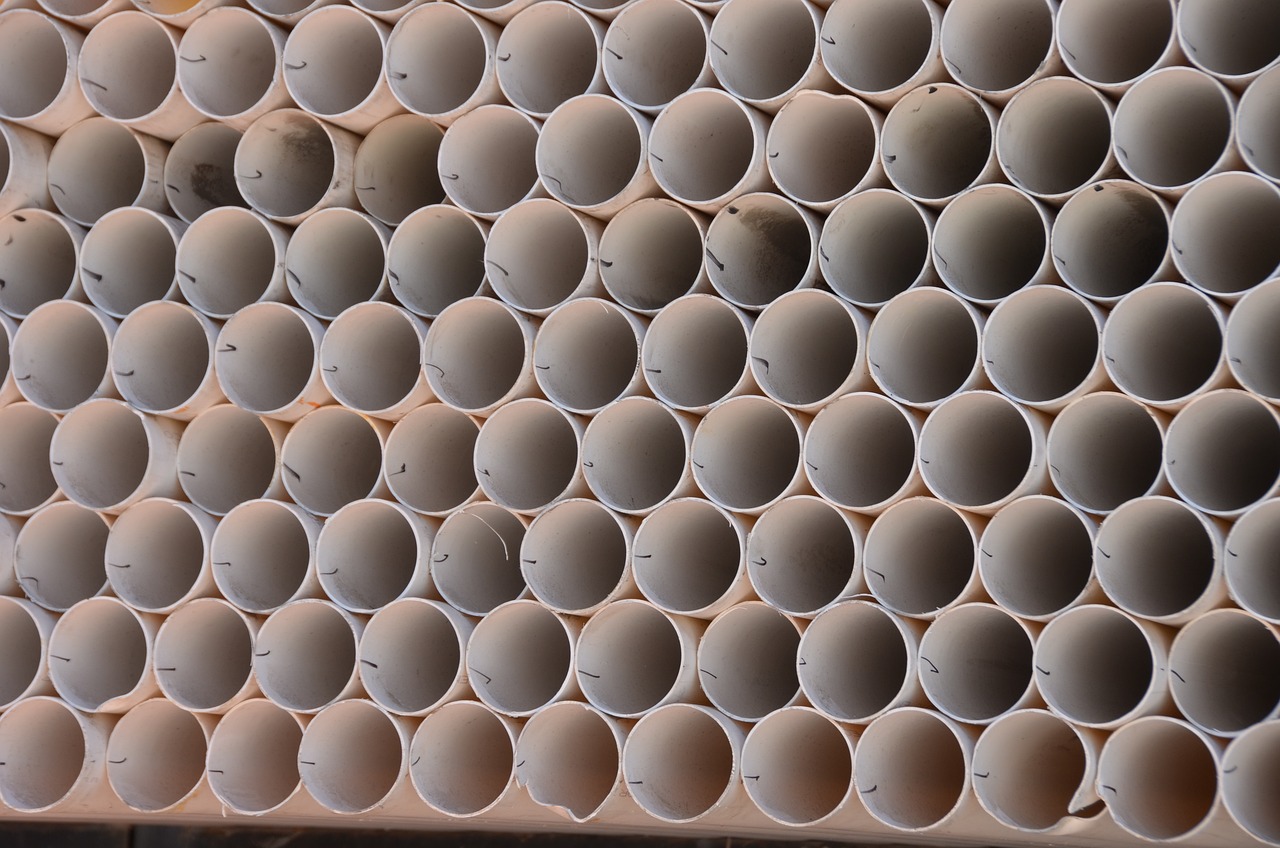

- Pipes

- Fittings

- Valves

- SOLAR PV SYSTEM

- Accessories

- Building Materials

- KITCHEN SERIES

- BATHROOM SERIES

- OTHERS - NON BUILDING MATERIALS

Mastering Pipe Fittings: A Comprehensive Guide to Selection, Prevention, Reuse, and Measurement (2024)

May, 27 2024

Author: Unitrade

Share This With

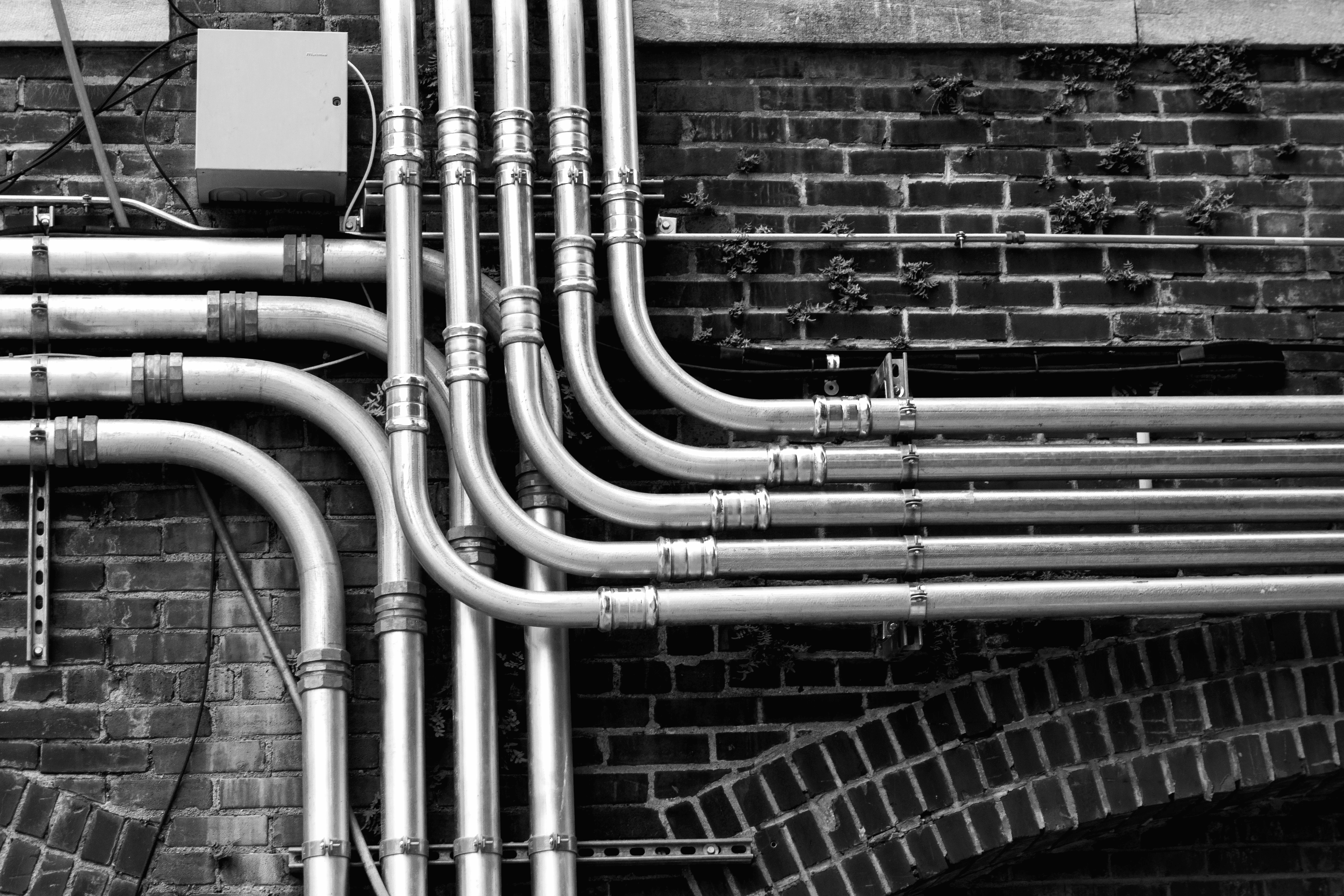

An often overlooked yet vital part of any piping system, pipe fittings are a resource to invest heavily in to ensure system integrity. With the ability to affect liquid or gas flow, as well as prevent accidents caused by leakage, they are essential for efficient and reliable system operation.

What are Pipe Fittings

Pipe fittings are components used to connect, terminate, control flow, or adapt the direction of piping systems. They are integral parts of plumbing and piping systems, found in various industries and applications where fluids or gases are transported. Pipe fittings come in various shapes, sizes, and materials to suit different requirements.

Types of Pipe Fittings

Pipe fittings come in various types, each serving a specific function within a piping system. Here are some of the most common types:

- Elbows: Elbows change the direction of piping, typically at angles of 45 degrees or 90 degrees. They help to navigate around obstacles or to make turns in the pipeline.

- Tees: Tees allow a pipe to split into two branches at a 90-degree angle. They are commonly used in plumbing systems to create intersections or to distribute flow.

- Reducers: Reducers connect pipes of different sizes. They come in two types: concentric reducers, which maintain a common centerline for the pipes, and eccentric reducers, which offset the centerlines.

- Couplings: Couplings join two pipes together in a straight line. They come in various forms, such as threaded couplings, which screw onto the pipe ends, and slip-on couplings, which are slipped over the pipe ends and secured in place.

- Unions: Unions are similar to couplings but allow for easier disassembly of pipes for maintenance or repairs. They consist of three parts: a male end, a female end, and a nut that joins them together.

- Caps and Plugs: Caps seal the end of a pipe, while plugs seal openings in fittings. They prevent leaks and contamination of the piping system.

- Crosses: Crosses are similar to tees but have a fourth opening at a 90-degree angle, allowing the pipe to split into three branches. They are less common than tees but used in situations requiring multiple branch connections.

- Flanges: Flanges are flat, circular discs with holes for bolts. They connect pipes, valves, and other equipment in a piping system. Flanges provide a convenient way to assemble and disassemble piping components.

- Adapters: Adapters connect pipes of different materials or sizes. They may have different types of connections on each end, such as threaded, slip-on, or welded connections.

- Nipples: Nipples are short sections of pipe with male threads on both ends. They are used to extend or connect fittings.

- Valves: Although not strictly fittings, valves are essential components in piping systems for controlling the flow of fluids or gases. They come in various types, such as ball valves, gate valves, and globe valves.

These are some of the most common types of pipe fittings, but there are many more specialised fittings available for specific applications and industries.

Uses of Pipe Fittings

Pipe fittings serve various functions within piping systems and are essential for constructing, maintaining, and regulating the flow of fluids or gases. Here are some common uses for pipe fittings:

1. Connecting Pipes

Pipe fittings connect sections of pipe, allowing for the creation of a continuous pipeline. They enable the extension of piping systems over long distances and around obstacles.

2. Changing Direction

Fittings such as elbows change the direction of piping. They enable pipes to navigate around obstacles or make turns in the pipeline without disrupting the flow of fluids or gases.

3. Branching and Distributing Flow

Tees and crosses allow a single pipe to split into multiple branches, facilitating the distribution of flow to different areas or equipment within a system. They are commonly used in plumbing systems and industrial processes.

4. Reducing or Increasing Pipe Size

Reducers connect pipes of different sizes. They ensure a smooth transition between pipes of varying diameters, allowing for efficient flow and preventing obstructions.

5. Sealing and Terminating

Caps and plugs seal the ends of pipes and fittings, preventing leaks and contamination of the system. They are often used during construction or maintenance to seal off unused openings or cap off sections of piping.

6. Joining Dissimilar Materials

Adapters connect pipes or fittings of different materials or sizes. They provide compatibility between different piping components, allowing flexibility in system design and construction.

7. Allowing for Disassembly

Unions are fittings that allow for easy disassembly of pipes or equipment for maintenance or repairs. They consist of three parts – a male end, a female end, and a nut – which can be easily disconnected and reconnected without needing to cut or weld.

8. Regulating Flow

Valves, although not strictly fitting, are often included in piping systems to control the flow of fluids or gases. They allow for starting, stopping, or regulating the flow within a system, providing control over process variables such as pressure, temperature, and flow rate.

9. Connecting to Equipment

Flanges connect pipes to valves, pumps, tanks, and other equipment within a piping system. They provide a secure and leak-proof connection, allowing easy installation, maintenance, and replacing equipment.

Overall, pipe fittings play a crucial role in the functionality, efficiency, and safety of piping across various industries, including plumbing, manufacturing, chemical processing, oil and gas, and many others.

Pipe Fittings in Systems

Pipe fittings are indispensable components within various systems, serving multifaceted roles critical for their functionality and integrity. Pipe fittings are used in a wide range of systems across several industries. Some common types of systems where pipe fittings are utilised include:

1. Plumbing Systems

Pipe fittings are extensively used in residential, commercial, and industrial plumbing systems for transporting potable water, wastewater, and gas. They are essential for connecting pipes, fixtures, valves, and appliances, ensuring proper flow and drainage.

2. Heating, Ventilation, and Air Conditioning (HVAC) Systems

HVAC systems use pipe fittings to circulate hot and cold water, refrigerants, and air throughout buildings. Fittings connect pipes to boilers, chillers, air handlers, radiators, and other HVAC equipment, facilitating heating, cooling, and ventilation.

3. Process Piping Systems

In industrial settings, pipe fittings are critical components of process piping systems used in chemical processing, oil and gas refining, pharmaceutical manufacturing, food processing, and other industries. These systems transport various fluids and gases, requiring fittings to connect equipment, control flow, and maintain system integrity.

4. Fire Protection Systems

Pipe fittings are integral to fire protection systems, including sprinklers and fire hydrants. Fittings connect pipes to sprinkler heads, standpipes, valves, and pumps, ensuring the reliable distribution of water for fire suppression.

5. Water Supply and Distribution Systems

Municipal water supply and distribution systems rely on pipe fittings to transport water from treatment plants to homes, businesses, and public facilities. Fittings connect pipes to water mains, service lines, fire hydrants, valves, and metres, enabling the delivery of clean water for domestic and industrial use.

6. Industrial Fluid Handling Systems

Various industrial processes require fluid handling systems for transporting liquids and gases. Pipe fittings are essential for connecting pipes, tanks, vessels, pumps, compressors, and other equipment involved in chemical processing, power generation, pulp and paper manufacturing, and more.

7. Oil and Gas Transmission Systems

Oil and gas transmission pipelines use pipe fittings to transport crude oil, natural gas, and petroleum products over long distances. Fittings connect pipeline sections, valves, pumps, and storage facilities, ensuring the safe and efficient distribution of energy resources.

8. Wastewater Treatment Systems

Wastewater treatment plants utilise pipe fittings to transport sewage, wastewater, and industrial effluent for treatment and disposal. Fittings connect pipes to treatment units, clarifiers, digesters, aeration tanks, and outfall structures, facilitating the treatment and removal of contaminants.

These are just a few examples of the diverse systems in which pipe fittings are used. Overall, pipe fittings are indispensable components of infrastructure, manufacturing processes, and environmental systems, contributing to the efficient and reliable transportation of fluids and gases across various applications.

NPT vs BSPT Fittings

“NPT” and “BSP” refer to two different standards for pipe threads for two different world regions. Here’s a brief overview of each:

| NPT | BST | |

| Nations/Regions it is Used in | United States and Canada. | United Kingdom, Europe, Asia, and some parts of Africa |

| Shape | Are measured in nominal sizes, with the diameter decreasing slightly towards the end of the fitting. | These threads do not taper; instead, they maintain the same diameter throughout the length of the fitting. |

| Sizes Available (in inches) | 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, | 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″ |

| Usages | Are often used in plumbing, hydraulic, and pneumatic systems. | Are used for interconnecting and sealing pipes and fittings |

| How the Threads Work | These threads create a seal by wedging the threads together when tightened. | These threads work by mating an external (male) thread with an internal (female) thread. |

It’s important to note that NPT and BSP threads have different angles and profiles, so attempting to connect NPT and BSP fittings can lead to leaks or damage to the threads. If you need to connect fittings with different thread standards, you’ll typically use adapters or couplings designed for that purpose.

When working with pipe fittings, always ensure that you are using the correct thread standard for your application to ensure proper sealing and compatibility.

Pipe Fittings Cost

The cost of pipe fittings might vary for a variety of reasons, such as manufacturer, type, size, material, or purpose of use. That being said, the local material supplier Unitrade puts their pipe at RM3.30-11,500.

Pipe Fittings Supplier Malaysia

To summarise, pipe fittings are key to the functionality, efficiency, and security of any plumbing system. By understanding how to select the right fittings, prevent leaks, reuse fittings responsibly, and measure accurately, you can ensure the proper functioning and longevity of your next piping system.

To ensure a fruitful construction project, make sure to invest in the most premium of pipe fittings. To see what Unitrade, one of the biggest local material suppliers, has to offer in terms of the fittings, explore their company website and product listings today.

FAQ:

How do I select the right pipe fitting for my application?

When selecting pipe fittings, consider material compatibility, fitting type for the intended function, size and dimensions matching those of the pipes, pressure and temperature ratings, compatibility with other system components, and environmental factors.

How do I prevent leaks in pipe fittings?

To prevent leaks, ensure proper installation following manufacturer guidelines, use sealant or tape on threaded fittings, avoid over-tightening, inspect fittings regularly for damage, and monitor system pressure for early leak detection.

Can I reuse pipe fittings?

Whether pipe fittings can be reused depends on their condition and circumstances. Before reuse, inspect fittings for damage, use proper disassembly techniques, clean thoroughly, and consider the type of fitting and its condition. Follow manufacturer guidelines and apply fresh sealant during reinstallation.

How do I measure pipe fittings?

Measure pipe fittings accurately using callipers or a measuring tape for diameter, and a thread gauge for threaded fittings. Refer to industry standards or manufacturer specifications, take precise measurements to avoid errors, and consult professionals or manufacturers for guidance if needed.

-

Category

Construction & Buildings -

Tags

Everything You Need to Know About Poly Pipe: A 2024 Guide

Read moreForging the Future: A Comprehensive Guide to The Enduring Legacy of Structural Steels in Construction (2024)

Read moreA Guide to Mastering Pressure Switches: Functionality, Applications, and Maintenance (2024)

Read moreMastering Pipe Fittings: A Comprehensive Guide to Selection, Prevention, Reuse, and Measurement (2024)

Read moreChoosing Between PVC and Poly Pipes: A Comprehensive Comparison (2024)

Read moreGalvanised Iron (GI) Pipe Fittings, Joints & Connectors

Read moreWhat is Fibreglass Insulation (Pros and Cons, Alternatives)

Read moreStainless Steel Flexible Hose Guide & Supplier Malaysia (2024)

Read moreWhat are uPVC Fittings? (Types, Advantages, Applications)

Read morenewsletter Subscription

Sign Up Now & Stay Tune With Our Latest News & Product Updates!