- ALFRAN - OUR HOUSE BRAND

- Pipes

- Fittings

- Valves

- SOLAR PV SYSTEM

- Accessories

- Building Materials

- KITCHEN SERIES

- BATHROOM SERIES

- OTHERS - NON BUILDING MATERIALS

Choosing Between PVC and Poly Pipes: A Comprehensive Comparison (2024)

May, 24 2024

Author: Unitrade

Share This With

In the industrial business, two types of pipes are much sought after: PVC pipes and poly pipes. Their cost-conscientious budget and heightened durability make them valuable assets in any plumbing system.

Due to them both being made of plastic, and their similarities in applications and properties, they are compared to and mistaken for each other frequently. However, while similar, there are some key differences between the two, and understanding these differences can make the difference between your project’s success or failure.

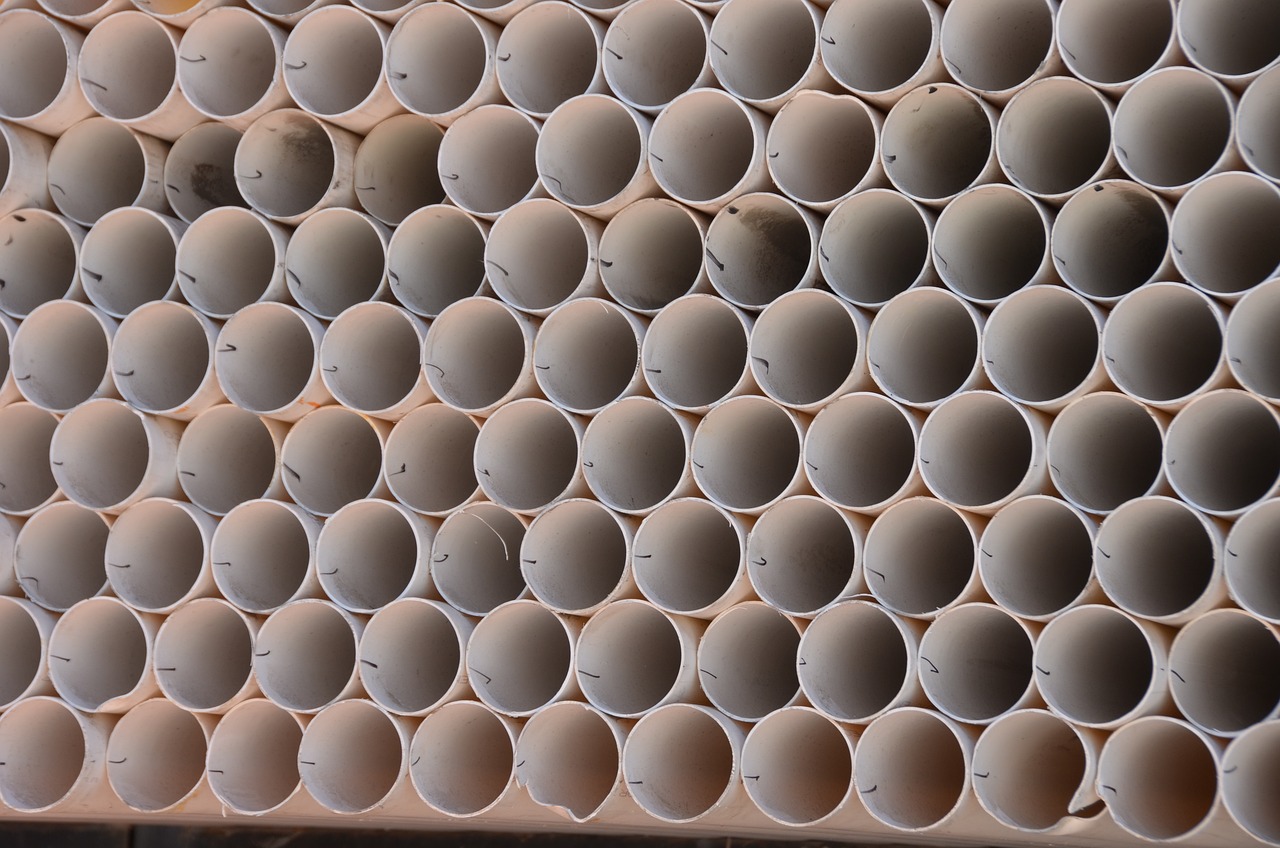

What are PVC Pipes?

PVC pipes are a type of plastic piping commonly used in plumbing, drainage systems, and other applications. PVC stands for polyvinyl chloride, a synthetic polymer made from vinyl chloride monomers. PVC pipes are known for their durability, affordability, and resistance to corrosion, making them popular for various construction and plumbing projects.

These pipes come in various sizes and are often used for carrying pressurised and non-pressurized liquids, underground drainage systems, irrigation, and vent piping. They are lightweight, easy to install, and require minimal maintenance compared to other materials like metal or concrete. PVC pipes are also resistant to chemical corrosion and are typically cheaper than alternatives such as metal or copper pipes.

What are Poly Pipes?

Poly pipes, short for polyethylene pipes, are a type of plastic piping widely used in various applications, including plumbing, irrigation, water distribution, and gas transportation. Polyethylene is a thermoplastic polymer composed of long chains of ethylene monomers. There are different types of poly pipes, but two common varieties are high-density polyethylene (HDPE) and low-density polyethylene (LDPE).

High-Density Polyethylene (HDPE) Pipes are known for their strength, flexibility, and resistance to corrosion and chemicals, making them ideal for water distribution, industrial use, and mining. Available in various sizes, they excel in high-pressure applications. In contrast, Low-Density Polyethylene (LDPE) Pipes have lower strength despite being more flexible, and are typically used in low-pressure applications like drip irrigation and landscaping.

Poly pipes offer several advantages, including flexibility, corrosion resistance, ease of installation, and longevity. They are lightweight, which makes transportation and handling easier. Additionally, poly pipes are often joined using heat fusion or mechanical fittings, providing leak-resistant connections.

Overall, poly pipes are a versatile and cost-effective solution for various piping needs in various industries and applications.

Poly Pipe Grades

HDPE poly pipes are available in several different grades and specifications, all designed for a variety of applications. In Malaysia, the most common grade of HDPE pipes used is either PE80 or PE100. While they have similar hardness and strength, PE100 improves on PE80 in terms of thickness, having a thinner wall thickness and overall being more lightweight.

Besides pipe grade, HDPE pipes are also categorised by class. The classes are the following:

- HDPE PN 6

- HDPE PN 8

- HDPE PN 10

- HDPE PN 12.5

- HDPE PN 16

- HDPE PN 20

The higher the pipe class, the more resistant to pressure the pipe is. These classifying details help identify the most useful pipes in a plumbing system.

The Versatility of PVC Pipes vs Poly Pipes

Depending on the usage required, both PVC and poly pipes can be used for a variety of situations.

Uses for Poly Pipes

Poly pipes are widely employed across industries for their versatility, durability, and cost-effectiveness. Common applications include:

- Agricultural Irrigation: Poly pipes help distribute water to crops due to their flexibility and resistance to root intrusion.

- Landscaping: These pipes help with watering gardens, lawns, and ornamental plants, often in drip irrigation systems or as underground conduits.

- Underground Electrical Conduit: Poly pipes protect electrical wiring and cables underground, offering insulation and moisture resistance.

- Water Supply Lines: Transporting non-potable water in various settings like industrial processes, construction sites, and temporary networks is an application poly pipes excel in.

- Drainage Systems: These pipes help collect and transport stormwater, wastewater, and other liquids, resistant to corrosion and facilitating efficient flow.

- Geothermal Systems: Poly pipes can transfer heat exchange fluids between the ground and buildings, boasting excellent thermal conductivity and chemical resistance.

- Gas Distribution: Poly pimples are approved for natural gas distribution systems, offering corrosion resistance and a lightweight alternative to metal pipes.

- Mining Operations: Poly pipes help transport slurries, tailings, and abrasive materials, with outstanding resistance to abrasion, corrosion, and chemicals.

- Municipal Infrastructure: Poly pipes are used in water mains, sewer lines, and stormwater management systems for municipal infrastructure projects.

- Aquaculture: These types of pipes aid with supplying water, managing wastewater, and facilitating circulation in aquaculture facilities, resistant to saltwater corrosion.

Uses for PVC

PVC pipes are highly versatile and widely utilised across various industries due to their durability, versatility, and cost-effectiveness. Common applications for PVC pipes include:

- Plumbing Systems: PVC pipes are used extensively in residential and commercial plumbing for water supply, wastewater management, and venting due to their corrosion resistance, smooth interior surfaces, and easy installation.

- Water Distribution: PVC pipes are employed in municipal water supply networks for distributing potable water, ensuring long-lasting performance and corrosion resistance.

- Drainage and Sewer Systems: These types of pipes are commonly used for carrying wastewater away from buildings, offering resistance to chemical degradation and preventing clogs.

- Irrigation Systems: The pipes are utilised in agricultural and landscaping irrigation for efficient water distribution to crops, gardens, and lawns, with various size options available.

- Stormwater Management: PVC pipes are employed in collecting and transporting rainwater runoff, featuring resistance to abrasion, corrosion, and environmental factors.

- Electrical Conduit: PVC pipes serve as protective conduits for electrical wiring and cables in buildings, providing insulation and mechanical protection against moisture and damage.

- HVAC Systems: These pipes are used in heating, ventilation, and air conditioning systems for conveying air, condensation, and drainage, offering thermal insulation and resistance to condensation.

- Industrial Applications: PVC pipes are utilised in various industrial processes for conveying fluids, chemicals, and gases, thanks to their chemical resistance and durability.

- Construction and Infrastructure: PVC pipes are employed in construction projects for underground utilities such as water mains, sewer lines, and drainage systems, as well as for structural applications like scaffolding and building supports.

- Aquaculture: PVC pipes are used in marine environments for water circulation, aeration, and piping systems due to their resistance to saltwater corrosion and cost-effectiveness.

When comparing these two materials, both PVC and poly pipes have a wide variety of applications across industries and sectors. PVC pipes are commonly used in plumbing, water distribution, drainage, and electrical conduit systems. In contrast, poly pipes are favoured for agricultural irrigation, landscaping, underground electrical conduit, and specialised applications such as geothermal systems and mining operations. The choice between PVC and poly pipes often depends on factors such as the project’s specific requirements, environmental conditions, cost considerations, and regulatory standards.

Pressure Tolerance of PVC Pipes vs Poly Pipes

Due to their differences in composition, PVC and poly pipes have different tolerances for pressure:

1. PVC Pipes

PVC pipes can handle high-pressure applications, making them suitable for water distribution systems, irrigation, and industrial processes. They are manufactured to meet specific pressure ratings, with standard PVC pipes available in pressure classes ranging from Schedule 40 to Schedule 80, and sometimes higher for specialised applications. PVC pipes have a smooth interior surface, which helps maintain consistent flow and minimise pressure losses within the pipe. Due to their excellent pressure tolerance, PVC pipes are commonly used for both pressurised and non-pressurized applications.

2. Polyethylene (Poly) Pipes

Polyethylene pipes, particularly those made of high-density polyethylene (HDPE), also have excellent pressure tolerance. HDPE pipes are known for their high strength-to-density ratio, allowing them to withstand significant internal pressures without deforming or rupturing. They are commonly used in water distribution systems, gas transportation, and industrial applications where high-pressure conditions are encountered. Poly pipes are available in various pressure ratings, typically denoted by the material’s Standard Dimension Ratio (SDR), with lower SDR numbers indicating higher pressure ratings.

In summary, PVC and polyethylene pipes offer excellent pressure tolerance, making them suitable for several applications requiring pressurised fluid transport. PVC pipes are commonly used in water distribution systems and industrial processes, while polyethylene pipes, particularly HDPE pipes, are favoured for their high strength and durability in demanding environments.

Durability of PVC Pipes vs Poly Pipes

In terms of durability, both PVC (polyvinyl chloride) pipes and polyethylene (poly) pipes have their respective strengths and weaknesses:

| PVC Pipes | Poly Pipes | |

| Longevity | Have a long service life, often lasting several decades when installed correctly. | Have a relatively long service life, with estimates ranging from 50 to 100 years under normal operating conditions |

| Resistance | Are resistant to rust, corrosion, and biological growth, which can prolong their durability. | Have resistance to corrosion, abrasion, and biological growth. |

| Probability of Cracking | Are rigid and may be prone to cracking or breaking upon impact, especially in cold temperatures. | Are highly flexible and resistant to bending, which makes them less susceptible to damage from ground movement, seismic activity, or frost heave. |

| Probability of Deforming | Are less likely to deform under heavy loads | Are more likely to deform under heavy loads due to their flexibility. |

Both PVC and poly pipes offer good durability for their intended applications. Proper installation, maintenance, and adherence to recommended operating parameters are essential for maximising the durability of either type of pipe.

Resistance of PVC Pipes vs Poly Pipes

In comparing PVC (polyvinyl chloride) and polyethylene (poly) pipes in terms of resistance, several factors need consideration:

1. Chemical Resistance

PVC Pipes: Offer excellent resistance to a wide range of chemicals, acids, and alkalis, making them suitable for various applications involving corrosive substances.

Poly Pipes: Exhibit good chemical resistance, but their performance can vary depending on the specific grade of polyethylene and the types of chemicals involved. Special formulations may be required for particular chemical applications.

2. Corrosion Resistance

PVC Pipes: Are highly resistant to corrosion from soil, water, and chemicals, contributing to their long-term durability and suitability for underground installations.

Poly Pipes: Are resistant to corrosion, particularly HDPE pipes, which are commonly used in aggressive environments such as mining and industrial applications.

3. UV Resistance

PVC Pipes: Are susceptible to degradation when exposed to UV radiation from sunlight, leading to discolouration, brittleness, and reduced mechanical strength over time. This is especially seen in above-ground applications.

Poly Pipes: Exhibit better UV resistance than PVC pipes, making them suitable for above-ground applications where exposure to sunlight is unavoidable.

4. Abrasion Resistance

PVC Pipes: Offer moderate resistance to abrasion but may be prone to wear over time, especially in applications involving abrasive materials or high-velocity flows.

Poly Pipes: Are exceptionally resistant to abrasion, making them suitable for applications where friction and wear are significant factors, such as mining and slurry transport.

5. Impact Resistance

PVC Pipes: Are relatively rigid and may be prone to cracking or breaking upon significant impact or stress, especially in colder temperatures.

Poly Pipes: Due to their thermoplastic nature, polyethylene pipes, particularly HDPE pipes, are more flexible, and therefore have superior impact resistance and toughness, making them less prone to damage from handling, installation, or external forces.

6. Heat Resistance

PVC Pipes: Have limited heat resistance and may soften or deform at elevated temperatures.

Poly Pipes: Polyethylene pipes, especially HDPE pipes, offer better heat resistance and are suitable for applications involving hot water distribution and industrial processes. However, their maximum temperature tolerance may still be limited compared to other materials.

PVC and poly pipes offer resistance to various environmental factors and mechanical stresses, but their performance characteristics differ. PVC pipes excel in chemical and corrosion resistance but may be susceptible to UV degradation and less flexible than poly pipes. Polyethylene pipes, on the other hand, offer superior flexibility, UV resistance, abrasion resistance, and impact resistance, making them suitable for a broader range of applications, especially those involving challenging environments or demanding operating conditions.

Installation of PVC Pipes in Comparison to Poly Pipes

When comparing PVC and polyethylene pipes for installation, several key factors emerge:

- Flexibility: PVC pipes are rigid, requiring special fittings for bends, whereas polyethylene pipes are highly flexible, simplifying installation around obstacles and in shifting terrain.

- Ease of Handling: PVC pipes are lightweight and easy to handle, especially above-ground, while polyethylene pipes, though similarly lightweight, demand cautious handling to prevent damage.

- Joining Methods: PVC pipes use solvent cement or mechanical fittings, necessitating precise preparation for leak-proof connections, whereas polyethylene pipes employ heat fusion techniques, ensuring strong, seamless joints without additional fittings.

- Terrain Adaptability: PVC pipes may need extra fittings for uneven landscapes, adding complexity to installation, whereas polyethylene pipes adapt readily to terrain changes, reducing the need for fittings in irregular areas.

While both PVC and poly pipes have their merits, polyethylene pipes offer advantages in flexibility, handling ease, and adaptability to challenging terrain, whereas PVC pipes excel in lightweight handling and standard joining methods.

Comparing Prices: PVC vs Poly Pipes

Prices of any pipes may depend on several external factors such as the amount needed, size and length of pipes, application needed, and the manufacturer of the pipes in question. Therefore, it is difficult to compare the prices of these two products. However, Unitrade, a trusted pipe supplier in Malaysia, sells PVC pipes at prices that range from RM 11.40-893. For poly pipes, however, you will need to call them and ask for their prices yourself.

Poly Pipe Supplier Catalogue

With the aid of modern technology, it is easier than ever to browse through selections of poly pipes and order some for your next construction project. Here is a compilation of the poly pipes available from Unitrade, one of the best local pipe suppliers in the market:

1. HDPE PN10 Pipe

| Brand | Buteline |

| Model | PN 10 |

| Colour | Black |

| Diameter Size | 20mm, ~63mm |

| Pipe Length | 100.0 meters |

| Price | Enquire Unitrade for pricing |

2. HDPE PN10 Pipe (Blue Stripe)

| Brand | Buteline |

| Model | PN 10 (Blue Stripe) |

| Colour | Black |

| Diameter Size | 90mm |

| Pipe Length | 50.0 meters |

| Price | Enquire Unitrade for pricing |

3. HDPE PN12.5 Pipe

| Brand | Buteline |

| Model | PN 12.5 |

| Colour | Black |

| Diameter Size | 25mm, ~50mm |

| Pipe Length | 100.0 meters |

| Price | Enquire Unitrade for pricing |

4. HDPE PN12.5 Pipe (Blue Stripe)

| Brand | Buteline |

| Model | PN 12.5 (Blue Stripe) |

| Colour | Black |

| Diameter Size | 63mm, ~90mm |

| Pipe Length | 50.0 & 100.0 meters |

| Price | Enquire Unitrade for pricing |

5. HDPE PN16 Pipe

| Brand | Buteline |

| Model | PN 16 |

| Colour | Black |

| Diameter Size | 90mm |

| Pipe Length | 50.0 meters |

| Price | Enquire Unitrade for pricing |

6. HANSEN H.D.P.E PN12.5 Pipe

| Brand | HANSEN |

| Model | PN 12.5 |

| Colour | Black |

| Diameter Size | 25.3mm, 32.2mm, 40.4mm, and 50.4mm |

| Pipe Length | 6 meters |

| Price | Enquire Unitrade for pricing |

7. HANSEN H.D.P.E PN16 Pipe

| Brand | HANSEN |

| Model | PN 16 |

| Colour | Black |

| Diameter Size | 20.3mm |

| Pipe Length | 6 meters |

| Price | Enquire Unitrade for pricing |

8. BUTELINE – HE20 P.E Pipe

| Brand | Buteline |

| Model | PN 20 |

| Colour | Black |

| Diameter Size | 20 mm |

| Pipe Length | 50.0 meters |

| Price | Enquire Unitrade for pricing |

PVC and Poly Pipe Supplier Malaysia

Both PVC and poly pipes are two well-known materials that are particularly accessible in the construction industry. Having applications for irrigation, and water systems, as well as use in buildings commercial and residential, these two types of pipes are creditable to use in any construction project you may have.

Understanding which pipe you will need takes time to take into consideration what you need the most in your project, as well as professional advice from experts in the field. To discover the best PVC and poly pipes, as well as obtain premium consultation opportunities, visit Unitrade’s website today.

FAQ:

Are PVC and poly pipes safe for drinking water?

Yes, both PVC and polyethylene pipes are considered safe for conveying potable water, as they do not leach harmful substances into the water and have been approved for use in drinking water applications by regulatory authorities.

How do I choose between PVC and poly pipes for my project?

The ultimate choice you make between PVC and poly pipes depends on the project’s specific requirements, environmental conditions, cost considerations, and regulatory standards. PVC pipes may be more suitable for certain applications like underground plumbing, while poly pipes may be preferred for flexibility and resistance to ground movement.

Can PVC and poly pipes be used interchangeably?

In some cases, yes, but it depends on the specific requirements of the application. PVC and poly pipes have different properties and installation methods, so it’s essential to consider the specific needs of the project before choosing between them.

Are PVC and poly pipes recyclable?

Yes, both PVC and polyethylene are recyclable materials. PVC pipes can be recycled into new PVC products, while polyethylene pipes can be recycled into a variety of plastic products.

How long do PVC and poly pipes last?

Both PVC and poly pipes have long service lives, typically ranging from 50 to 100 years or more, depending on factors such as installation conditions, maintenance, and environmental factors.

-

Category

Construction & Buildings -

Tags

Everything You Need to Know About Poly Pipe: A 2024 Guide

Read moreForging the Future: A Comprehensive Guide to The Enduring Legacy of Structural Steels in Construction (2024)

Read moreA Guide to Mastering Pressure Switches: Functionality, Applications, and Maintenance (2024)

Read moreMastering Pipe Fittings: A Comprehensive Guide to Selection, Prevention, Reuse, and Measurement (2024)

Read moreChoosing Between PVC and Poly Pipes: A Comprehensive Comparison (2024)

Read moreGalvanised Iron (GI) Pipe Fittings, Joints & Connectors

Read moreWhat is Fibreglass Insulation (Pros and Cons, Alternatives)

Read moreStainless Steel Flexible Hose Guide & Supplier Malaysia (2024)

Read moreWhat are uPVC Fittings? (Types, Advantages, Applications)

Read morenewsletter Subscription

Sign Up Now & Stay Tune With Our Latest News & Product Updates!