- ALFRAN - OUR HOUSE BRAND

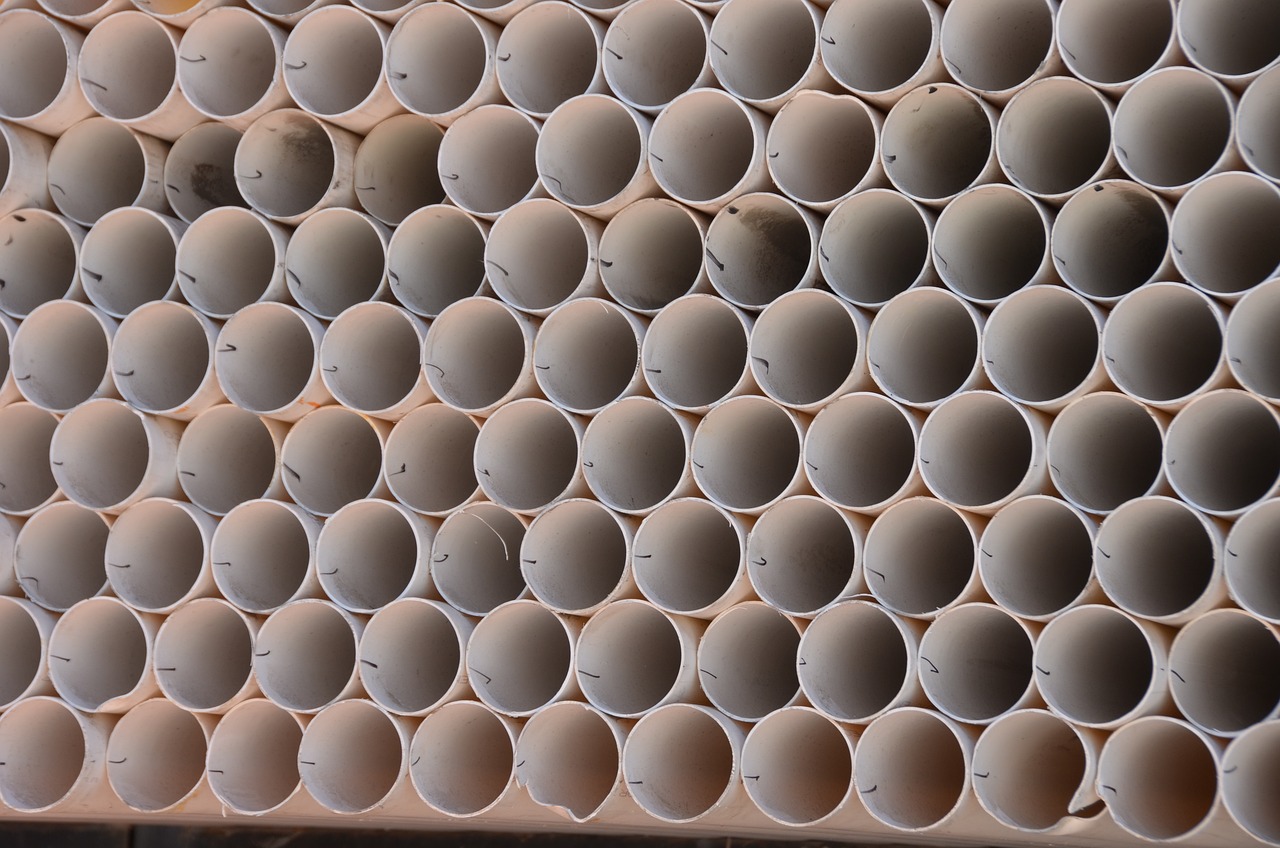

- Pipes

- Fittings

- Valves

- SOLAR PV SYSTEM

- Accessories

- Building Materials

- KITCHEN SERIES

- BATHROOM SERIES

- OTHERS - NON BUILDING MATERIALS

Copper Water Pipes Guide (2024): Types, Benefits, Disadvantages

March, 21 2024

Author: Unitrade

Share This With

Modern plumbing requires copper water pipes, which have long been favoured because of their dependability and durability. These pipes are essential for maintaining effective and safe water distribution in both residential and business settings because of their resistance to corrosion and antibacterial qualities. The main advantages and numerous uses of copper water pipes will be discussed in this article, highlighting their importance in modern plumbing systems.

Key Benefits and Properties of Copper Water Pipes

Copper pipes offer unparalleled durability, excellent corrosion resistance, and antimicrobial properties, ensuring a safe and long-lasting water supply. They are lead-free, impermeable to contaminants, and versatile for various applications. Additionally, copper’s recyclability emphasises its sustainability, making it an eco-friendly choice in plumbing.

1. Durability and Longevity

Copper pipes are not only known for their long lifespan and resistance to wear and tear but also their historical use for thousands of years demonstrates their proven track record. The material’s inherent durability reduces the need for frequent replacements, translating into cost-effectiveness and reliability for users. Its superiority in underground environments, where other materials may fail due to natural occurrences, underlines copper’s unyielding robustness.

2. Corrosion Resistance

Copper’s excellent ability to resist corrosion is unmatched, which is crucial in plumbing to prevent leaks and maintain the water supply’s integrity. Its resistance to a wide range of environmental conditions, including the capacity to withstand contact with various soils and waters without corroding, makes it an ideal choice for long-term infrastructure projects.

3. Antimicrobial Properties

The antimicrobial properties of copper, which inhibit the growth of harmful bacteria and other pathogens, contribute to the safety of drinking water systems. This is an essential feature for public health, as copper’s natural characteristic helps in maintaining a contaminant-free and healthy water supply.

4. Lead-free and Safe

Copper is the original lead-free piping material, ensuring a non-toxic environment for water transport. With current regulations mandating low-lead content and the availability of lead-free solders and fluxes, copper piping systems offer a reliable, safe choice for drinking water without the risks associated with lead contamination.

5. Impermeability and Quality Control

The impermeability of copper means that external contaminants, such as chemicals and petroleum products, cannot penetrate the material to compromise the water quality. This aspect is critically important for service lines located in potentially contaminated environments. Additionally, the leaching properties and potential health effects of copper are well understood and controlled, ensuring the material’s safety and reliability.

6. Versatility in Applications

Copper’s versatility extends to its use in various applications, from heavy-duty underground use to heating systems and low-pressure residential applications. The variety of copper pipe types—K, L, and M—cater to different demands and situations, demonstrating copper’s adaptability.

7. Sustainability

Copper’s sustainability is reflected in its recyclability with no loss of properties. It can be repurposed indefinitely, maintaining its value and reducing environmental impact. The long life cycle of copper, coupled with its high recycling rate, asserts copper’s position as an environmentally responsible choice.

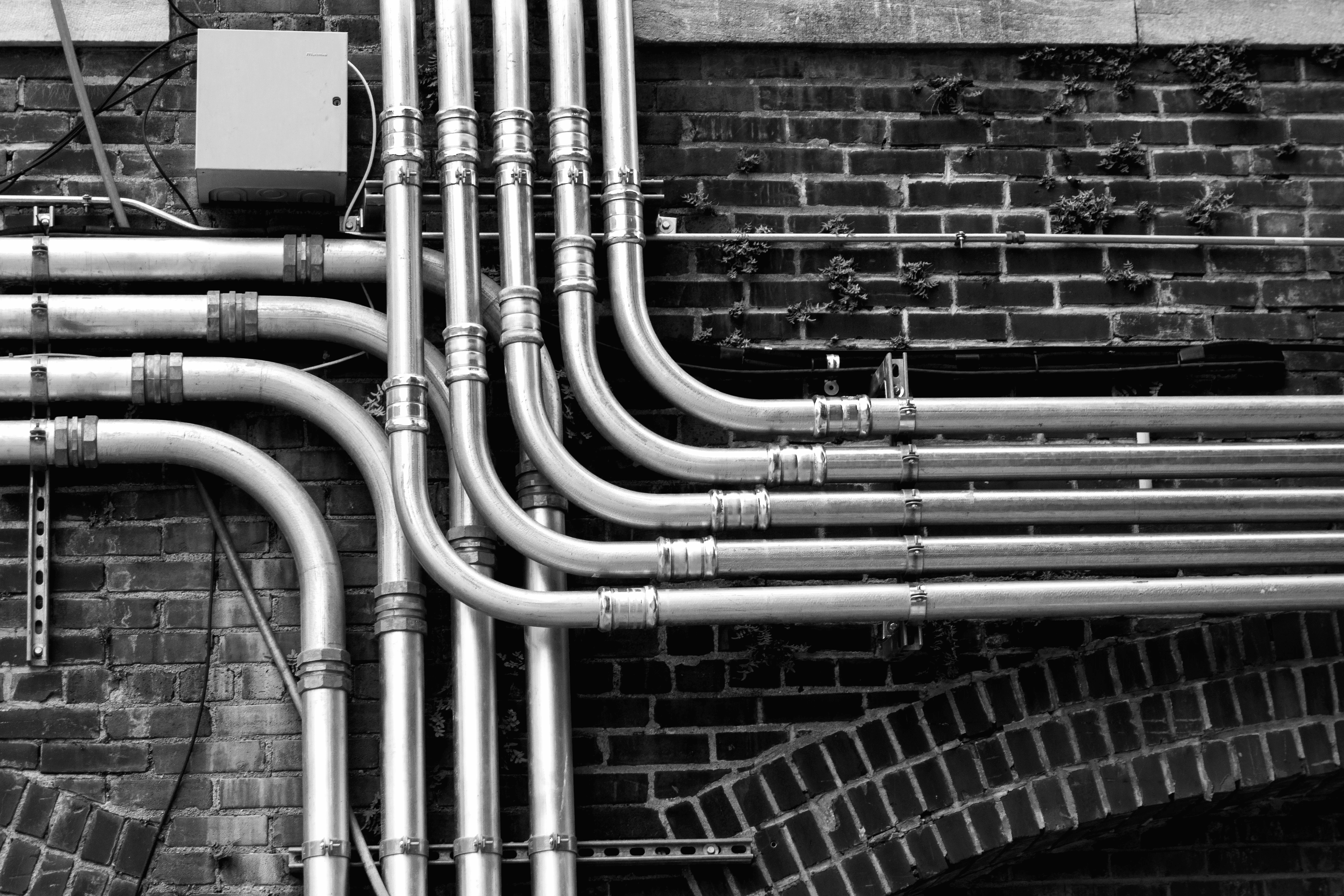

Installation, Maintenance, and Sustainability

Installation Techniques

Precise measurement and cutting of copper pipes are essential before installation. With a multi-tool such as a hacksaw or reciprocating saw, or a pipe cutter, you might be able to cut the pipes as accurately as feasible.

Since soldering is the typical technique for joining copper water pipes, two supplies are required for this process: solder and a propane torch. Consequently, employing this method ensures a tight seal, which is very beneficial in preventing water leaks from the copper pipes.

During installation, check that all fittings are tight and positioned correctly to prevent leaks. Copper pipes are ideal for use with copper fittings.

Maintenance Tips

Some quick maintenance tips for everyone is to ensure periodic check for signs of corrosion or damage, particularly at joints and bends and only use mild, non-abrasive cleaning agents to clean copper pipes.

Avoid using harsh chemicals such as hydrochloric, sulfuric or nitric acids as these harsh chemicals can pollute the water in the pipes, making the water pH value goes below 7.0. That makes the water acidic and can corrode the water pipes.

Sustainability Aspects

Because copper is highly recyclable, the environmental impact of using it in plumbing is reduced. Because of its ability to transport heat, copper is extremely energy-efficient in heating and cooling systems. Because copper pipes last a long time and don’t need to be replaced often, they encourage sustainable building practices.

Copper water pipes need to be installed and maintained with extreme precision in order to maximise their lifespan and functionality. Their sustainability highlights copper’s standing as an eco-friendly plumbing material, particularly with regard to energy efficiency and recyclability.

Comparative Analysis of Copper Water Pipes with Other Materials

| Feature/Aspect | Copper Pipes | PVC Pipes | PEX Pipes | Steel Pipes |

| Durability | High (long lifespan) | Moderate (can warp under high temp) | Moderate (can be damaged by UV) | High |

| Cost | Higher | Lower | Lower | Moderate to High |

| Installation Ease | Requires soldering | Easy (no soldering required) | Very easy (flexible) | Challenging (heavy) |

| Heat Tolerance | Excellent | Poor (prone to warping) | Moderate | Good |

| Flexibility | Rigid | Rigid | Highly flexible | Rigid |

| Corrosion Resistance | Good | Excellent chemical resistance | Good | Can corrode in acidic environments |

| Thermal Conductivity | High | Low | Low | Moderate |

| Suitability for Outdoor Use | Yes | Limited (UV sensitive) | Limited (UV sensitive) | Yes |

| Water Impact Quality | Antimicrobial properties | Neutral | Neutral | Can affect if corroded |

Each material performs well in a variety of applications and has unique advantages. Because of its strength, heat resistance, and antibacterial properties, copper is the preferred material for long-term installations, especially when water purity and temperature stability are critical. PVC and PEX are more cost-effective, easier to install, and suitable for a variety of interior applications. Steel is often used in industrial environments due to its strength and durability. Financial limitations, environmental issues, and the specific requirements of the plumbing system all play a role in the material selection process.

Types of Copper Pipes

Copper pipes, utilised extensively in plumbing, are distinguished not only by their sizes but also by the wall thickness, which determines their specific applications. Here’s a comprehensive look at the various types of copper pipes based on their thickness and uses.

Type K Copper Pipes

Type K copper pipes has the thickest wall among the pressure-rated types. Its robustness lends itself well to situations where pipes must withstand significant external pressures or environments, such as underground installations. Type K is available in both hard straight sections and in rolls for soft annealed tubing.

Predominantly used for underground service, including beneath sidewalks and streets. They often require corrosion protection such as a polyethylene sleeve. This type also finds its application in the refrigeration industry, indicated by its green-coloured printing in the United States.

Type L Copper Pipes

Featuring a thinner wall than Type K, Type L is a versatile choice that balances durability with ease of installation. This type can be found in both hard and soft forms, depending on the installation requirements.

It is the go-to for residential and commercial water supply and pressure applications. With its blue-coloured printing in the United States, it signifies a medium thickness that accommodates a wide range of uses.

Type M Copper Pipes

With an even thinner wall section, Type M is lighter and more cost-effective but is limited to lower-pressure applications. Type M copper pipes are typically found in hard straight sections. It is suitable for residential and light commercial heating applications, and identified by its red-coloured printing in the United States.

Type DWV Copper Pipes

Type DWV copper pipes have the thinnest wall section and are not pressure rated.nThey are used exclusively for drain, waste, and vent lines, where the absence of pressure allows for thinner walls. They are typically marked with yellow or light orange printing. Found in specific sizes like 1+1⁄4, 1+1⁄2, and 2 inches, these pipes are usually available as hard straight sections.

The nominal size designation in North American plumbing is 1⁄8th inch less than the actual outside diameter, and the inside diameter varies with wall thickness. Despite the various thicknesses, the outer diameter remains consistent across Types K, L, and M, simplifying compatibility with fittings.

The refrigeration sector differentiates pipes further with the ACR designation, which is compatible with the lubricants used in air conditioning systems, indicating wall thickness and size based on the outside diameter directly.

Europe

While North America uses imperial units for copper pipe sizes, the metric system is the norm in Europe, with EN 1057 standard specifying Types X, Y, and Z, each with its unique wall thickness and application area.

Australia and New Zealand

In Australia, copper pipes are classified as Types A, B, C, and D and referenced to their DN number, a nominal millimeter equivalent to their actual imperial size. Notably, while Australian and New Zealand plumbing codes are the same, their sizing is based on different diameter measurements: New Zealand uses nominal bore (internal diameter), while Australia uses nominal diameter (external diameter), leading to a discrepancy when comparing their sizes to North American standards.

Conclusion

In conclusion, copper water pipes have proven to be essential to modern plumbing due to their extended lifespan, resistance to corrosion, and antibacterial properties. They are a popular alternative for both residential and business settings because of its versatility and environmental characteristics, such as recyclable materials. While alternative materials like PVC, PEX, and steel have advantages of their own, copper’s unique blend of properties ensures its continued importance in the plumbing industry.

Once you’ve settled up your selection, visit UNITRADE and explore their highly-durable copper pipes and more!

FAQ

Why is copper tubing a popular choice for water lines in both residential and commercial buildings?

Copper tubing is a popular choice for water lines because of its durability, corrosion resistance, and antimicrobial properties. Its versatility makes it suitable for a variety of applications, including cold water supply lines, and it complies with building codes. Copper’s thermal rating also ensures it performs well under various temperature conditions.

How does the type of copper pipe affect the application in plumbing systems?

The type of copper pipe—such as Type K, L, M, or DWV—affects its application based on wall thickness and pressure rating. Type K pipes, with their thicker walls, are ideal for underground and high-pressure applications, whereas Type L and M are commonly used for general residential and commercial buildings. Type DWV is used for drain, waste, and vent lines where no pressure is present.

Can copper piping be affected by acidic water?

While copper material has excellent corrosion resistance, acidic water can pose a risk over time. Building codes often require copper alloys in piping to mitigate this risk. The manufacturing process also ensures that copper pipes can handle a range of pH levels, but it’s important to monitor for acid water, which can accelerate copper corrosion.

Any concerns regarding dangerous emissions and transporting medical gases?

Copper pipes do not emit dangerous emissions and are safe for transporting medical gases. Copper tubing is often chosen for medical gas systems due to its cleanliness and non-reactivity, ensuring that gases are not contaminated or imparted with a metallic flavour.

-

Category

Construction & Buildings -

Tags

Everything You Need to Know About Poly Pipe: A 2024 Guide

Read moreForging the Future: A Comprehensive Guide to The Enduring Legacy of Structural Steels in Construction (2024)

Read moreA Guide to Mastering Pressure Switches: Functionality, Applications, and Maintenance (2024)

Read moreMastering Pipe Fittings: A Comprehensive Guide to Selection, Prevention, Reuse, and Measurement (2024)

Read moreChoosing Between PVC and Poly Pipes: A Comprehensive Comparison (2024)

Read moreGalvanised Iron (GI) Pipe Fittings, Joints & Connectors

Read moreWhat is Fibreglass Insulation (Pros and Cons, Alternatives)

Read moreStainless Steel Flexible Hose Guide & Supplier Malaysia (2024)

Read moreWhat are uPVC Fittings? (Types, Advantages, Applications)

Read morenewsletter Subscription

Sign Up Now & Stay Tune With Our Latest News & Product Updates!