- ALFRAN - OUR HOUSE BRAND

- Pipes

- Fittings

- Valves

- SOLAR PV SYSTEM

- Accessories

- Building Materials

- KITCHEN SERIES

- BATHROOM SERIES

- OTHERS - NON BUILDING MATERIALS

What is Steel Scaffolding? (Advantages, Types, Supplier Malaysia)

April, 02 2024

Author: Unitrade

Share This With

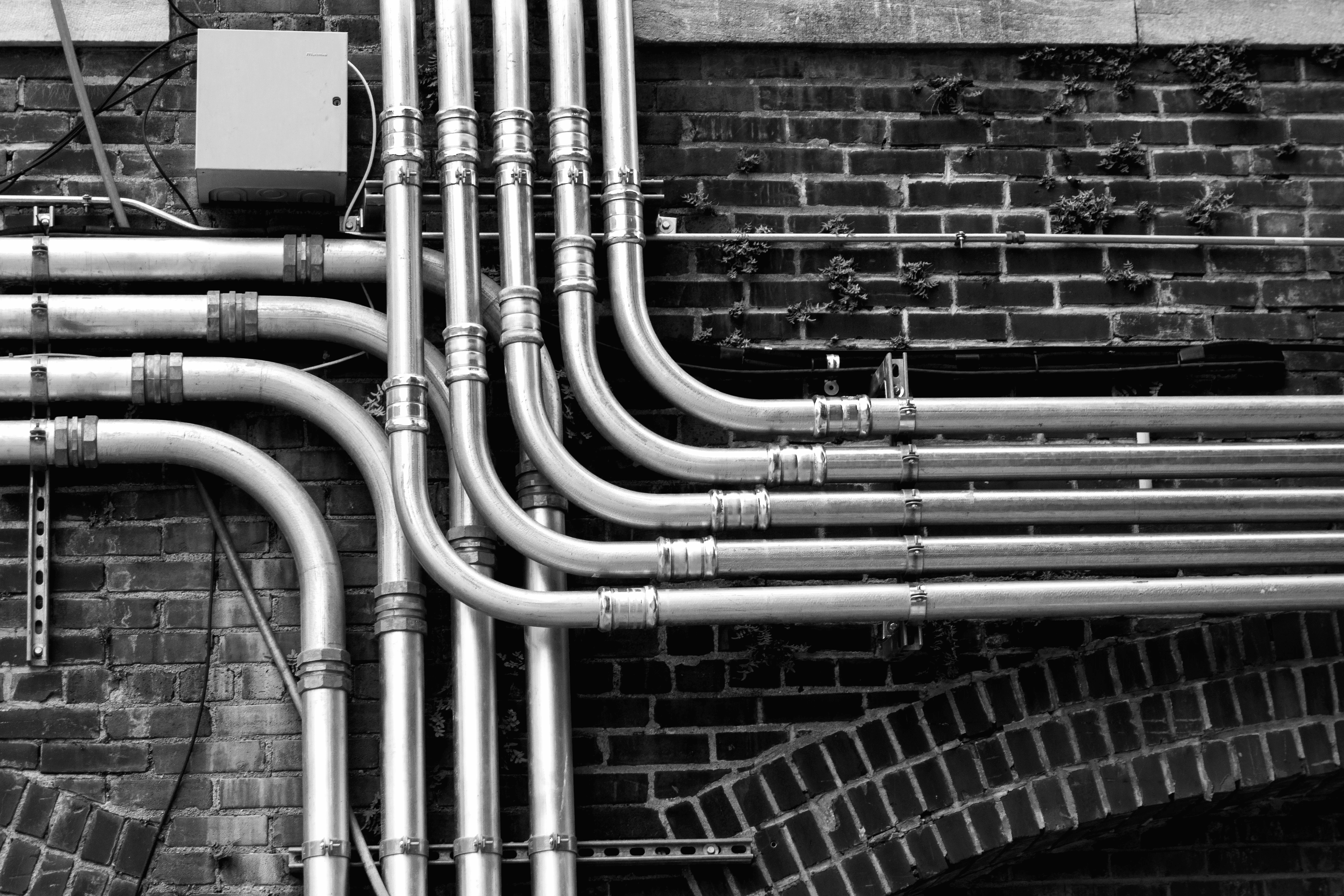

Steel scaffolding is an indispensable component in the construction industry, providing a robust framework for workers to execute tasks efficiently and safely at elevated heights.

What is Steel Scaffolding?

Steel scaffolding is a temporary structure designed to support construction workers, materials, and equipment during building erection, maintenance, or renovation tasks. With unparalleled strength, durability, and versatility, steel scaffolding offers a reliable platform for workers to navigate and operate at varying heights with utmost confidence.

Steel scaffolds find applications across a wide spectrum of construction projects, ranging from high-rise buildings and infrastructure developments to industrial facilities and residential complexes

Types of Steel Scaffolding

Steel scaffoldings are crafted from high-quality steel tubes and fittings, There are several types of steel scaffolds, each with their own unique qualities and applications to enhance safety, productivity, and efficiency on the job site:

Single Scaffolding

Also known as bricklayer’s scaffolding, this type is the simplest and most common. It comprises vertical standards supported by the ground, spaced regularly along the structure’s length. Horizontal ledgers parallel to the wall provide a work platform. Typically used for brickwork and masonry tasks under 5 meters in height.

Double Scaffolding

Referred to as mason’s scaffolding, it offers greater stability than single scaffolding. Two rows of standards are constructed parallel to the wall, with the inner row closer to the building and the outer row about 1 meter away. Horizontal ledgers fix to both rows, forming a sturdy framework. Commonly used for heavy-duty masonry and plastering.

Cantilever Scaffolding

Employed when ground-based scaffolding is impractical due to obstacles or limited space. The platform extends horizontally from the building or a previous scaffold using needles or cantilever beams. Requires careful engineering for stability and safety, often used for tall building repair and maintenance.

Suspended Scaffolding

Suspended from the roof or overhead structure using ropes, chains, or cables. Ideal for tasks like painting, cleaning, or maintenance on building exteriors. Workers hoist themselves up using a mechanical device or manual winch system. Offers access to challenging areas, perfect for high-rise structures.

Trestle Scaffolding

Also called horse scaffolding, it’s a simple and portable system used for interior finishing and low-level tasks. Consists of movable trestles, typically made of wood or metal, with planks laid across to create a working platform. Lightweight, easy to assemble, suitable for short-term or relocatable projects.

Steel Scaffolding

Constructed primarily from steel tubes and fittings, it offers superior strength, durability, and stability compared to wood or aluminum. Highly versatile, customizable to various configurations and load requirements. Widely used in projects prioritizing safety, reliability, and longevity.

Patented Scaffolding

Innovative systems developed by manufacturers with patented features enhancing safety, efficiency, and usability. Incorporates components like rapid assembly mechanisms, adjustable height configurations, and integrated safety enhancements. Known for reliability and performance in construction projects.

Steel Scaffolding Components

Steel scaffolding is a complex structure composed of various components designed to offer a safe, stable, and adaptable platform for construction and maintenance work. Each component plays a crucial role in ensuring the integrity, safety, and efficiency of the scaffolding system. Here are the key components of steel scaffolding:

- Base Plates or Adjustable Base Jacks: These are the foundation of the scaffolding structure, placed at the bottom of the scaffold to distribute weight evenly and provide stability. Adjustable base jacks allow for height adjustment to ensure the scaffold remains level on uneven surfaces.

- Standards or Uprights: Vertical tubes that transfer the weight of the scaffold and its load to the ground. They run the entire height of the scaffold and are connected by the base plates at the bottom.

- Ledgers: Horizontal tubes that connect the standards to each other. They provide lateral support to the scaffold and can also support working platforms and guard rails.

- Transoms: These are placed perpendicular to the ledgers and provide additional support for the boards or platforms. Transoms help distribute the weight of the scaffold and its load across the ledgers.

- Diagonal Braces: Also known as cross braces, these are fitted diagonally between standards, ledgers, or transoms to provide rigidity and prevent the scaffold from swaying.

- Scaffold Boards or Steel Planks: These are the work platforms that workers stand on. Made of steel or sometimes wood, these planks provide a stable and secure surface for workers and materials.

- Guard Rails and Toe Boards: Guard rails are safety barriers placed along the edges of the scaffold platforms to prevent falls. Toe boards are raised edges that prevent tools or materials from falling off the scaffold.

- Scaffold Ties: These are used to secure the scaffold to the building or structure at various intervals to ensure stability, especially in tall or freestanding scaffolds.

- Couplers or Fittings: These are the metal components used to connect the tubes (standards, ledgers, transoms) together. There are various types of couplers, including right-angle couplers, swivel couplers, and sleeve couplers, each serving different purposes in the scaffold’s structure.

- Ladders or Staircases: These provide access to the different levels of the scaffold. They must be securely attached to the scaffold structure to ensure safe access.

- Steel Props: Adjustable steel props can be used for additional support, especially in structures requiring extra stability or bearing heavy loads.

Advantages and Disadvantages of Steel Scaffolding

While steel scaffolding offers numerous advantages such as robustness, longevity, and ease of assembly, it also presents certain considerations. On the positive side, steel scaffolding excels in terms of:

- Strength: Steel scaffolding boasts exceptional load-bearing capacity, making it suitable for supporting heavy construction materials and equipment.

- Durability: Steel is highly resistant to weathering, corrosion, and deterioration, ensuring the longevity of the scaffolding system even in harsh environmental conditions.

- Adaptability: Steel scaffolding can be customized and configured to fit various construction scenarios, allowing for flexibility and versatility on the job site.

However, it’s essential to consider the following disadvantages:

- Weight: Steel scaffolding is significantly heavier than alternative materials such as aluminum or fiberglass, which can pose challenges in transportation, handling, and assembly.

- Cost: The initial cost of steel scaffolding may be higher compared to other materials, although its durability and longevity often result in long-term cost savings.

- Rusting: Despite its corrosion resistance, steel scaffolding is still susceptible to rust over time, especially if not properly maintained. Regular inspections and maintenance are necessary to prevent rusting and ensure structural integrity.

- Conductivity: Steel is a good conductor of electricity, which may pose safety risks in certain environments, such as near power lines or during electrical work. Proper precautions must be taken to mitigate these risks.

By weighing the advantages and disadvantages of steel scaffolding, construction teams can make informed decisions regarding its suitability for their specific project requirements. With proper planning and adherence to safety protocols, steel scaffolding remains a reliable and widely used solution in the construction industry.

Steel Scaffolding Standards

The BS EN standard is most commonly used worldwide, particularly BS1139 and EN 39. That said, different countries have their own scaffolding standards specified by the respective governing bodies.

Each scaffolding standard determines the steal scaffolding tube/pipe’s tolerance, chemical makeup, and mechanical properties. They are aptly designed to be suitable for each country’s weather and project cost.

In Malaysia, the steel scaffolding standards for the materials, specifications, and design consists several standards:

- MS1462:Part 1:2012 (Steel frame scaffolding in prefabricated scaffolds)

- MS1462:Part 2-1:2010 (Steel tubes in tubular scaffolds)

- MS1462:Part 2-2:2010 (Aluminum tubes in tubular scaffolds)

- MS1462:Part 2-3:2011 (Steel & aluminium couplers, fittings, and accessories in tubular scaffolds)

- MS1462:Part 3-1:2011 (Steel & aluminum modular system scaffolding in prefabricated scaffolds)

- MS 1462:Part 3-2:2012 (Particular methods of structural design for steel & aluminum modular system scaffolding in prefabricated scaffolds)

- MS1462:Part 4-1:2013 (Performance requirements and general design)

Steel vs. Timber Scaffolding

While steel scaffolding, crafted from high-quality steel pipes and materials like carbon steel, offers unparalleled strength and durability, timber scaffolding remains a viable alternative for certain projects. Timber scaffolding, constructed from wooden planks and poles, provides a cost-effective solution for lighter, short-term construction tasks. However, when faced with heavy weight loads, adverse weather conditions such as heavy rain, or the need for a stable platform, steel scaffolding—especially heavy-duty steel scaffolding—proves superior. Its versatility is evident in various forms, including double steel scaffolding for enhanced stability and modular steel scaffolding systems for customizable configurations.

Innovations in Steel Scaffolding

Recent advancements in the steel industry have led to the development of supreme pipe and galvanised steel scaffolding, offering improved corrosion resistance and longevity. The geometries of steel pipe have been optimized to provide a balance between strength and weight, enabling the construction of light steel scaffolding with sufficient diameter for stability yet easy maneuverability. Furthermore, the introduction of mobile steel scaffolding towers and portable trestle steel scaffolding systems has revolutionized access in construction, allowing for safe and efficient movement across the site.

Elevating Construction Standards with Unitrade’s Steel Scaffolding Solutions

Unitrade stands at the forefront of the construction industry, offering innovative steel scaffolding solutions that redefine safety, efficiency, and performance standards. With a commitment to excellence, integrity, and customer satisfaction, Unitrade strives to empower construction teams with the tools and technologies they need to succeed in today’s dynamic and demanding environment. For more information about Unitrade and steel scaffolding rental services, check out our catalogue.

FAQ

What makes steel scaffolding materials like carbon steel superior to alternatives?

Steel scaffolding materials, particularly carbon steel and galvanized steel, offer exceptional durability, resistance to environmental factors such as corrosion, and a high duty steel scaffolding load capacity. These materials ensure a stable and steady platform that can withstand the demands of construction projects, from the heavy weight of materials to the challenges posed by heavy rain and strong winds.

How do adjustable steel base plates contribute to scaffolding safety and stability?

Adjustable steel base plates are a critical component in ensuring the stability of a scaffolding structure. They allow for precise leveling of the scaffold even on uneven surfaces, providing a stable foundation that reduces the risk of collapse. This adjustability is crucial for maintaining a safe access point to elevated work areas, especially when dealing with the variable geometries of construction sites.

What are the benefits of modular vs. normal steel scaffolding?

Modular steel scaffolding offers unparalleled flexibility and efficiency, featuring prefabricated sections that can be quickly assembled and disassembled. This system is ideal for projects requiring frequent configuration changes or those with complex structures. Normal steel scaffolding, while robust and reliable, lacks the rapid deployment and adaptability of modular systems but is well-suited for projects with straightforward, linear designs.

What considerations should be made for scaffolding in areas prone to heavy rain?

In regions where heavy rain is common, it’s essential to choose scaffolding materials that are resistant to rust and corrosion, such as galvanised steel or coated carbon steel. Proper drainage on the scaffolding platforms, the use of steel planks with non-slip surfaces, and regular maintenance to check for water-induced damage are also crucial for ensuring worker safety and the longevity of the scaffolding structure.

-

Category

Construction & Buildings -

Tags

Everything You Need to Know About Poly Pipe: A 2024 Guide

Read moreForging the Future: A Comprehensive Guide to The Enduring Legacy of Structural Steels in Construction (2024)

Read moreA Guide to Mastering Pressure Switches: Functionality, Applications, and Maintenance (2024)

Read moreMastering Pipe Fittings: A Comprehensive Guide to Selection, Prevention, Reuse, and Measurement (2024)

Read moreChoosing Between PVC and Poly Pipes: A Comprehensive Comparison (2024)

Read moreGalvanised Iron (GI) Pipe Fittings, Joints & Connectors

Read moreWhat is Fibreglass Insulation (Pros and Cons, Alternatives)

Read moreStainless Steel Flexible Hose Guide & Supplier Malaysia (2024)

Read moreWhat are uPVC Fittings? (Types, Advantages, Applications)

Read morenewsletter Subscription

Sign Up Now & Stay Tune With Our Latest News & Product Updates!